Iron cast parts are durable and last longer. They are used in various industries to create things such as machines and tools. Today, we'll be finding out what iron casting are, as well as how they are created, and discuss their importance in construction and product creation.

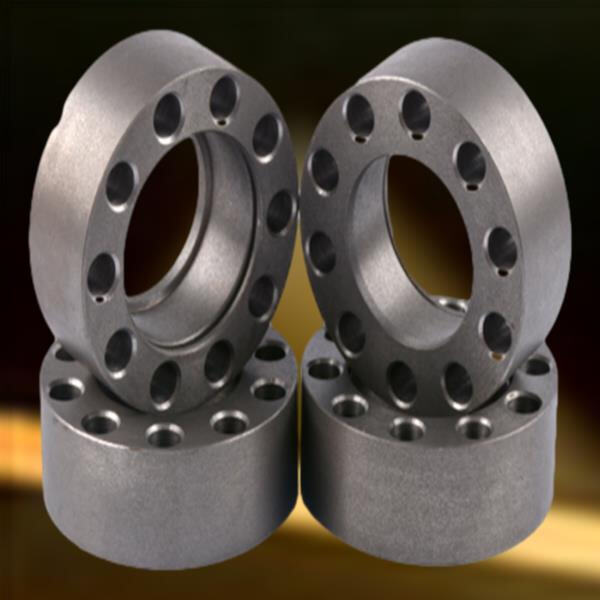

Casting Iron casting parts are produced by sand casting. In casting, hot molten metal is poured into a mold, which forms the desired shape. Then, it hardens when it cools. After that, the mold is removed, and you are left with a solid iron part. It's a technique used to make a lot of different types of iron parts, from small gears to large machine components.

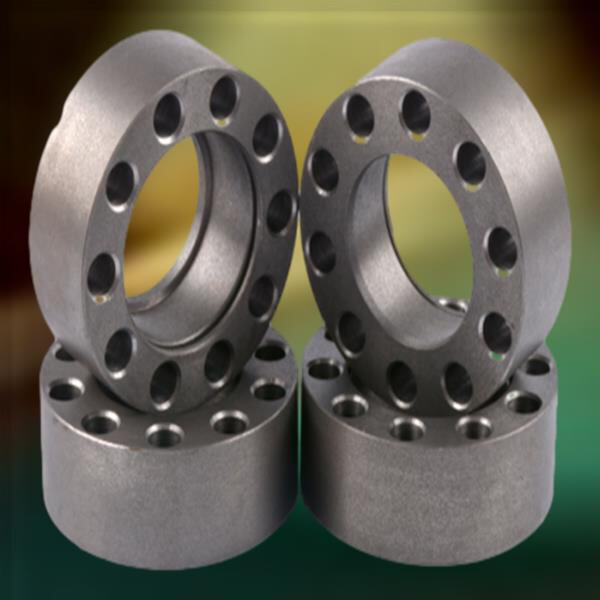

Iron Casting Parts used in The Factories There are many industrial reasons for using grey iron casting. One major cause is that they are strong. Iron components take tons of use and abuse, and that’s why they’re so great for heavy machinery. They also can stand up to heat and rust, and are good on heavy brute work.

To produce iron casting parts, you must have molds and hot metal. You begin by making a mold for the part you want to fabricate. Next, the mold is filled with the liquid iron through a special passage known as a sprue. The metal cools and solidifies inside the mold and is removed.

Iron casting parts have a wide range of applications, such as construction and machinery. In construction, they form beams, columns, and other highly resistant components. In this sector they are responsible for making tools, machinery, and equipment. They are also utilized in automobiles to manufacture engine and other parts.

Iron casting parts quality control is very important. It’s the quality control process to ensure parts are correctly made and function as intended, he said. This quality control involves testing the parts for strength and longevity. Manufacturers can produce dependable iron casting parts that satisfy what clients require by adhering to strict guidelines.