Ductile iron is known for its strength (and this will be the single biggest factor driving your ductile iron replacement cost). Ductility is the ability of material to resist it being fractured well by heavy objects (it will tear, but not fracture). This quality is crucial for inflexible, long-lasting components such as automobile body sections and heavy-duty equipment used in construction. If you think about all things that must be sturdy, ductile iron is the right choice in most cases.

One other REALLY KEY word that benefits the shoot is "ductility". Ductility is a fancy term to say that this material can be elongated or formed without shattering. One of the biggest strengths of ductile iron is its flexibility which makes it suitable to be cast in any shape and size. Its form is so malleable that it can be molded into nearly anything, from tiny pieces to giant structures which we daily use many things.

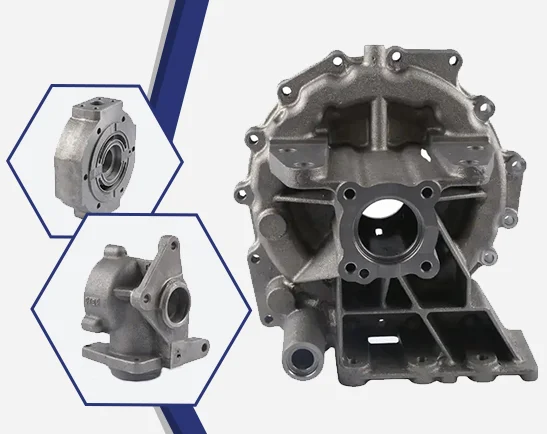

Ductile iron casting is not only about creating robust parts, part of its other facets lie in the variety that we make use and see every day. Many of the things we use every day would not exist because this process is part of creating these products. For instance, ductile iron is used in pipelines for drinking water and gas pipes, gears necessary to make machines operate properly as well major components of cars together with trucks. This equipment are important for our daily lives and also for our industry functioning.

So, what is the working principle of ductile iron casting? There are few important steps in this process. It starts with melting the iron in a furnace fully. The iron is now melted with a foundry torch, and the molten liquid metal slowly poured into an open mold. The shape of the mold is to what we want our end product to be shaped into. Melted iron is poured and cooled. When it is cool, this hardens to the shape of the mold itself.

And in this process of cooling, something magical happens. Iron is modified with magnesium as a chemical substance. It is a vital addition, as it allows the iron to be more malleable. When magnesium is added, the hard flakes of iron grains form tiny rounds instead Nanopatch causes the iron to perform better under stress and strain, which is crucial for most of its applications.

In addition to this, ductile iron is frequently employed in building projects and the likes; its strength makes it an unbeatable competitor. Because of this, it is worn like a coat in fabric structures moored at the corner; It can be said that no other material besides bar steel can design such strong beams as well as columns supporting buildings and all kinds of street lights resisting weather conditions or guidance sign posts to guide us. All of these things show just how versatile and practical ductile iron can be.

Ductile iron casting, which is a rather popular choice of many industries, for more than one reasons. The answer is - It largely due to the fact that it is one of the strongest material. Ductile iron is ductile, this expands it the ability to absorb and cancel from view forces providing strength compared just before most materials also given that momentum loads which afterward surrounded by bend causes other less brittle metal parts.

Our factory for casting is part of our company, which allows us to incorporate ductile iron casting and commerce. We provide lower rates and superior quality than 90% of our competitors. Because we eliminate middlemen, we offer cheaper prices and superior quality products directly from our factory to our clients.

Our production lines are automated, CNC machining centers, and surface treatment workshops that work together to provide technical assistance to support mass production. We have the capability to meet requirements of any ductile iron casting while maintaining production standards.

More than 100 customers have been helped by us, with fast precise and ductile iron casting. If you're looking for full customization or design-based customization we are able to meet a variety of customer needs. Our knowledge and experience guarantee that every customized project will meet the requirements of the client.

Our 24-hour customer support team ensures that all inquiries are ductile iron casting answered quotes are given within 6 hours and custom solutions are made available within 12 hours No matter what time or location our customers call us we can promptly respond to them and provide professional services to ensure that their needs are addressed promptly