Iron is one such metal, which when liquified becomes a hot liquid. This molten iron is then poured into a mold, which traps the shape of where the hot liquid has been placed. The molten iron will then cool and solidify in the shape of the mold. This how we make our cast iron goods. Cast Iron has been around a long time and even back to the ancient times! Today, using the new technology we can cast iron for multi types of some products that its all you used everyday.

As much as we might not think about it, there are a lot of cast iron products that show up in our daily lives. One major use of cast iron is for the manufacture of engine blocks, ring gears and drives from cars trucks. Engine parts play a vital role as they all work together in making your vehicle run smooth and ensures the efficiency. The absence of these pieces may function a hindering issue for the car to behavior effectively. Cast iron can also be used to produce water pipes and fittings for the construction industry. Water is an essential element that allows us to live, drink water, produce food you name it. In addition to these LF applications, ductile iron castings makes for great cookware which includes skillets and Dutch ovens. This is because of the cast iron itself being strong and also having a unique chemical approach towards heat that makes it incredibly suitable for different cooking.

You can find cast iron in a variety of products we see all around, like the manhole covers and drainage grates on your constructions. They are both very durable and the strongest of all other kinds. In fact, you could even drive over them your car and they would not break or damage. The fact that cast iron ductile iron is strong, hard and wear resistant makes it perfect for a variety of applications.

One of its most appealing facets is that it can support massive weights without tearing into pieces, which is one reason why cast iron cooking pans are so prevalent. Its great strength makes it very popular in construction and industrial scenes. Also, LF does well in extremely warm conditions because it can absorb and hold heat without melting. It is an excellent choice for applications that require great resistance to heat, such as cooking or in some industrial operations.

Another great advantage of using this material is the flexibility and adaptability it offers as cast iron is also very versatile. It is malleable and can be formed into various shapes or sizes depending on the specific requirements. Whether you need a cast iron foundry for some small, delicate device or an immense one for something big and heavy, cast iron can easily be produced to order. Further, LF items can be mass produced quickly and cheaply, which is often a priority for manufacturers with large quantities to produce all at once.

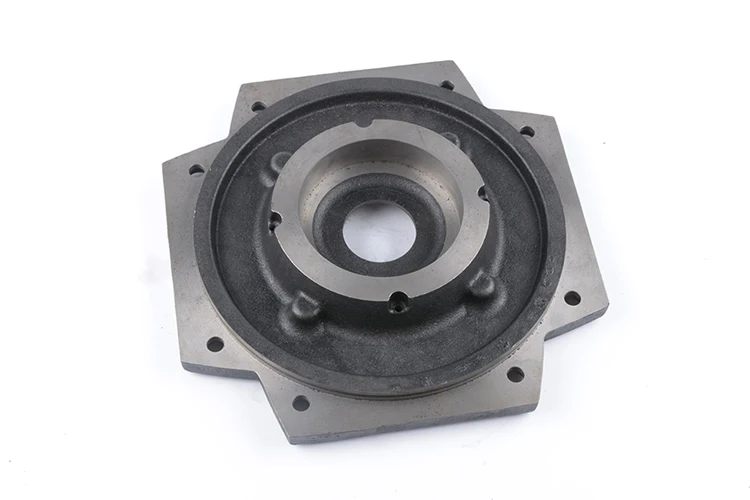

There are a series of critical steps involved in producing cast iron. Once iron casting parts is poured into a mold it must be left to cool and solidify. After the iron is allowed to cool and set, then the mold will be removed piece by piece as it shows a shiny new cast area. This new piece will likely need to be cleaned up so that it has a smooth finish without any jagged edges. This care is increased by polishing and sanding any defects or unevenness. The reason manufacturers do this is because it enables them to produce a great number of castings that are all identical This standard is important because it allows to create components that are expected to work together where they need well.

Making the most out of grey iron casting manufacturers. To keep your skillet non-stick and operating at its best for a long time, good care is essential. Without proper maintenance, cast iron can and will rust over time therefore always keep it well dry and oiled. Tips For Taking Care Of Cast Iron Cookware.

How to Clean Cast Iron - 1) To clean it warm water and a scrub brush is best in the case of cast iron skillet. Over time, using soap will cause your cast iron skillet to rust and ruin it. Regular cleaning and care will make sure your cast iron cookware performs well, year after year.

We have automated production lines CNC machining centers and surface treatment Cast iron castings that work in tandem to provide technical assistance to support mass production We have the manufacturing capability to fulfill requirements of any size and still maintain production standards

Our Cast iron castings is part of our company, which allows us to integrate production and commerce. We can offer lower pricing and better quality than the majority of our competition. We cut out the middleman and give our customers competitive prices, higher quality products, and direct from the factory.

We have Cast iron castings over 100 customizing customers, providing fast, accurate and efficient customization solutions. It doesn't matter whether it's complete customizing or design-based, we can meet various demands of customers. We make sure that each custom project is done to the highest standard.

Our customer service department is available 24/7 Cast iron castings that all queries are addressed within one hour while quotes are issued within six hours and customized solutions are offered within 12 hours We can respond promptly and professionally to our customers no matter which part of the world they are in or when they contact us