Photo credits: A Grey Iron Casting Company Special Place Where Men Make Things Out Of Metal The workers had worked hard to make the things we use in a lot of ways that are strong and firm. This article will delve deeper into what they do at Grey Iron Casting Company and how cast iron is transformed into items that are of utility.

A factory like Grey Iron Casting Company, where workers use machines as well as their skills and ability to make various metal items. They make a whole lot of money creating things like pipes, car parts and even kitchenware! Grey iron, which they are crafted with is a very strong metal and it will not let you down. The Casters (as the people who work there) They work together as a team to build amazing things which benefits people in their day-to-day life.

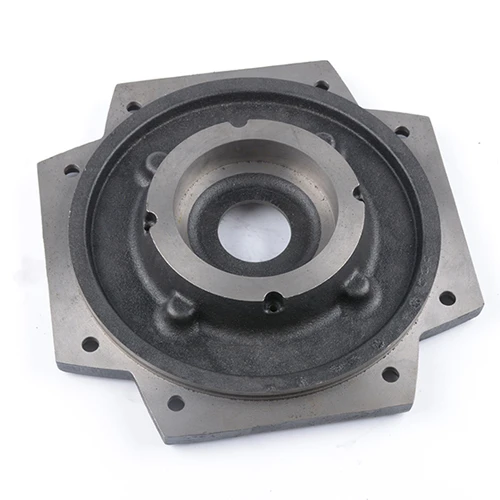

The production of grey iron is achieved through the mixing of various solids. They are made from iron, carbon and silicon called grey iron. This furnace, where they melt these materials together is a really hot place - like one big oven. After the metal liquefies/is melted, it is poured sensing a mold carefully. A mold is a container that can shape the metal to make it into what you want. Once it has been poured, the metal is left to cool and harden inside of this mold, where after cooling down completely transforms into a strong object that can be put to use in many ways.

Walk into any facility of a Grey Iron Casting Company and you are sure to find the workshop scattered with machines everywhere. Several workers are hard at work putting their heads together to generate various stainless steel aload_blocks. The casting-process wheels - in effect, melting the metal and forming it into commensurate shapes using huge machines. They also use multiple tools to complete the objects, perfecting them with additional processes such as hammers and chisels. Finally, the product finishes one more time to give it a nice coat and make sure they are prepared for use. Each toothbrush is assembled with diligence and precision by everyone at the company - after all, quality products are a result of hard work.

Grey Iron Casting Company is dedicated to making the highest quality products possible. They are meticulous about every detail and make it with the finest materials available. That makes sure that their products are tough and durable too. The business is dedicated to ensuring that their product aligns closely with the end users, hence they require such a gatekeeper. What this means is that when you purchase something from Grey Iron Casting Company, you will know with all certainty, it's the best product out there.

Motor Parts - This part of the company also makes various parts for cars like, transmission cases and engine blocks. The purpose of these parts does dam and reliable due to which they are responsible for providing a smooth-running vehicle presence on the road is maintained.

Pipes - They are used to make other product is the making of pipes. The pipes are used to carry liquids, gases and solids. These are built strong and have the capability to resist high pressures, making this most applicable in many industries.

Our grey iron casting company service department is available 24/7 assures that every inquiry is promptly answered and estimates are made within 6 hours and custom solutions are made available within 12 hours No matter when or where our customers reach out we can promptly respond and provide professional service ensuring their needs are met promptly

More than 100 customers have been helped by us, providing fast, accurate and effective solutions. We can meet a grey iron casting company of client needs regardless of whether it's full customization or design-based customization. We make sure that every custom-designed project is executed in the most professional manner.

Our factory for casting is part of our company, which allows us to incorporate grey iron casting company and commerce. We provide lower rates and superior quality than 90% of our competitors. Because we eliminate middlemen, we offer cheaper prices and superior quality products directly from our factory to our clients.

Our grey iron casting company are automated CNC machining centers and surface treatment workshops which work together to provide technical support for mass production Our manufacturing capabilities allow us to manage orders ranging from small to large quantities while maintaining high-quality production standards and efficiencies