Желязото е изключително здрав метал и се използва от векове. Желязото е метал, който ще намерите в неща като коли, самолети, сгради и мостове. Това е естествено срещан материал и един от най-широко разпространените метали на Земята! Но можем ли да превърнем желязото в различен метал, който лесно се топи – металът, наречен дуктилно желязо? Процесът е доста fascinиращ и допринася за още по-широкото приложение на желязото.

Когато се стопи желязо и смесим (в малка фракция) други метали заедно с мед, например "магнезий, церий", то може да се превърне в ковко желязо. Това превръща малки парченца от веществото, известно като графит, в желязото. Тези парченца графит са които помагат на метала да се кове по-лесно и също така го прави по-малко крехко. Работниците след това могат да използват ковкото желязо по различни начини.

Например, тръби от ковко желязо се използват за транспортиране на вода и други течности в много страни. Тъй като тези тръби са подложени на високо налягане, те трябва да са достатъчно здрави и да не са склонни към образуване на ръжда. Важно е да са издръжливи, за да не възникнат бързо проблеми, които могат да повлияят на работата на водните ни системи.

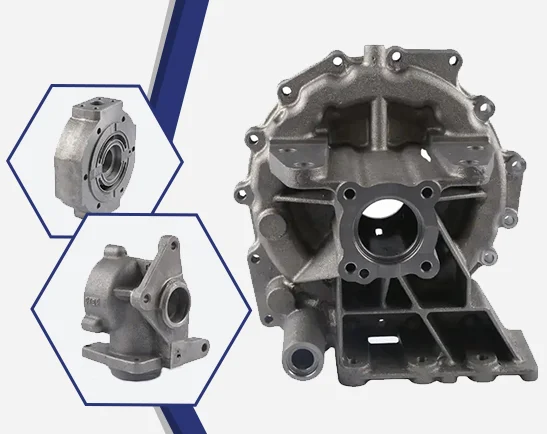

Този вид желязо също се използва при производството на различни части и аксесоари за машини и др. Тези части трябва да са устойчиви на висока температура и налягане, както и повечето от тях трябва да имат много тесни допуски. Такава прецизност е важна, защото дори най-малките грешки могат да доведат до неправилна работа на машините.

Едно голямо предимство на кованото желязо е, че може да се използва по разнообразни начини в различни индустрии. Различни автомобилни компоненти се произвеждат от ковано желязо, като например коляно валове, които помагат на двигателя да работи гладко, и разпределителни валове, използвани за контролиране на клапанното време. Различни видове машини като предавателни кутии, клапани и дори части за вятърни турбини, които генерират чиста енергия.

Кованото желязо е изключително мощно и издръжливо вещество. Но неговата гъвкавост е по-голяма в сравнение с други видове желязо – понякога достатъчно, за да го направи по-добър избор за дадено приложение. Кованото желязо също е много устойчиво към топлина, корозия и много различни химикали, което го прави отличен материал за употреба в различни форми.

Въпреки че индустрията на ковкото желязо има предизвикателства, все пак в компаниите се случват много положителни неща. Нови методи и технологии, които тези производители използват, за да разработват продукти от ковко желязо с добро качество, за полза на клиентите си. Те също трудно работят като мантри в индустрията и се погрижват тя да расте и процъфтява добре, за благото на всички.

През годините сме обслужвали клиенти на производители на ковък чугун, като им предоставяме бързи, точни и ефективни решения. Способни сме да задоволим широк спектър от изисквания на клиентите — независимо дали те имат нужда от пълна персонализация или от персонализация въз основа на даден дизайн. Нашите знания и опит гарантират, че всеки персонализиран проект ще отговаря на очакванията на клиента.

Нашият производствен капацитет за ковък чугун включва автоматизирани CNC-машинни центрове и работилници за повърхностна обработка, които работят в тясно сътрудничество, за да осигуряват техническа поддръжка за серийно производство. Производствените ни възможности ни позволяват да управляваме поръчки в обем от малки до големи количества, като запазваме високи стандарти за качество и производствена ефективност.

Нашата служба за клиентско обслужване, работеща 24/7, гарантира, че всички запитвания ще бъдат отговорени в рамките на един час, оферти ще бъдат изготвени в рамките на шест часа, а персонализирани решения ще бъдат предоставени в рамките на 12 часа. Независимо от времето или мястото, от което нашите клиенти ни се обаждат, ние ще реагираме незабавно и ще осигурим услуги за производители на ковки желязни изделия, като гарантираме бързото задоволяване на техните нужди.

Притежаваме собствена литейна фабрика и сме постигнали интеграция между производството и търговията. Предлагаме по-добри цени и по-високо качество в сравнение с повечето производители на ковки желязни изделия. Елиминираме посредниците и предоставяме на нашите клиенти по-конкурентни по цена и висококачествени продукти директно от завода.