Sand casting is an ancient process for casting metal. People been using it for a long time, and they’re still doing it today to make all kinds of cool stuff. Let’s learn more about it!

Sand casting is a process in which molten metal is poured into a mold made of sand. This has been the process for thousands of years. It’s popular because it’s simple and does its job well. With sand casting sand you can create large and small items.

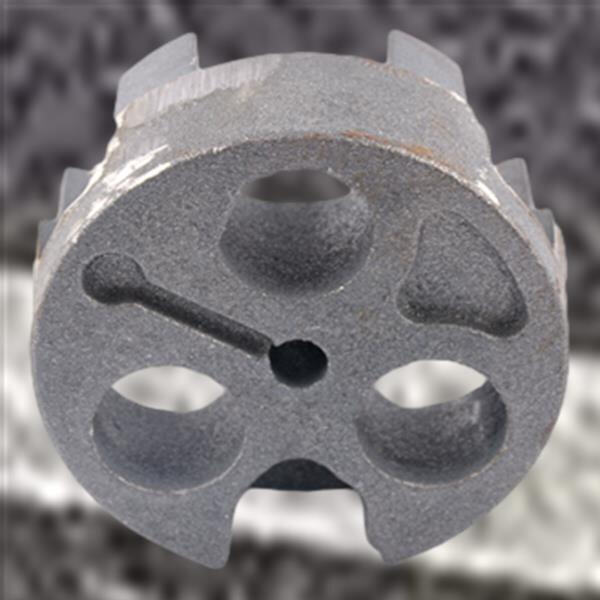

First, a mould is made from sand. The sand is squeezed tightly around a replica of the object you want to make. Next, the pattern is removed and liquid metal is poured into the mold. When the metal has cooled and hardened, the mold is broken off to reveal the metal object within. It feels like magic!

Old as iron sand casting may be, people have found the newest of the new technology to make it better. Now computers and machines can be used to create more accurate molds. As a result, we're able to make even more complex objects than we were before.

Sculptures aren’t the only things that come from sand casting. It is also employed to manufacture equipment parts of machines and machines in general as well as for vehicles. Also because sand casting can involve any type of metal, it’s used in a wide range of industries fabricating many things we use on a daily basis.

One of the wonderful things about sand casting is it can create special and unique pieces. As each mold is hand made, no two pieces are identical. This is why every sand-cast item is unique and one-of-a-kind. There are so many beautiful metal objects that artists could demonstrate their skill and creativity by making.