You have a training set that goes up to October 2023. It’s sort of like making sculptures out of metal. Precision grey iron castings can produce various things from airplane components and medical instruments to jewellery. LF is a precision castings company.

Precision castings can be used to shape metals into detailed objects. That’s an enormous amount of skill to get everything perfectly right. Precision castings: hot metal poured in to a mould and allowed to cool. It shaped the mold and cast a design in detail in metal.

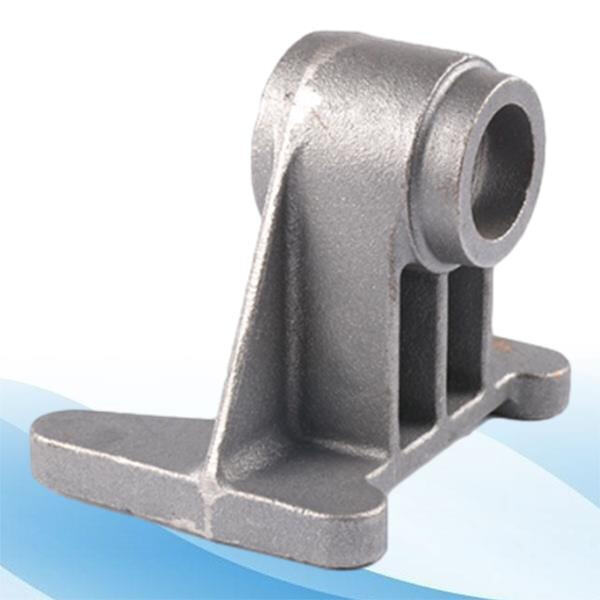

However, LF precision ductile iron castings must first begin with a mold. Once the process is complete, the metal will fill up the mold and create a shape. It is molded to shape the physical item. Once the mold is prepared the molten metal is poured and this cools and hardens. Once the metal has cooled, the mold is removed, revealing the final precision casting.

LF Precision gray iron castings is an intricate process and can be overwhelming at times. It begins with designing the product and creating a mold. The hot metal is poured into the mold and allowed to cool. They remove the mold and display the final result once the metal has hardened. The process involved in creating precision casting is quite complex so it requires strict methods to achieve accurate metal shapes.

It is advanced technology used for precision grey and ductile iron castings. The ranges from digitally-assisted metal forming technology to numerical bending equipment. This technology also assists in making precise measurements and designs that would have been difficult to do manually. It applies its technology to ensure that each precision casting is produced with exactitude and fidelity.

Once we have our quotations, the trick is to balance price vs precision. The precision ductile castings are practically works of art, with formed shapes and designs. Most of us appreciate the beauty of precision castings in any number of products, ranging from jewelry to airplane parts. It is proud to create beautiful, exacting precision castings that function well and look good.

We have served over 100 custom customers, offering quick, accurate and efficient customization solutions. If you're looking for full customization or design-based We can satisfy a Precision castings of needs of the customer. We ensure that every custom project is delivered at the highest quality.

Our customer service team is always available making sure that inquiries are responded to within a matter of hours quotations are sent within 6 hours and custom solutions can be delivered within Precision castings Whatever time or place our customers reach out to us we will respond promptly and offer professional assistance making sure their needs are satisfied quickly

We have Precision castings lines CNC machining centers and surface treatment workshops that collaborate to provide technical support for mass production Our manufacturing capabilities allow us to handle orders in large or small quantities while maintaining the highest quality production standards and efficiency

We own our own manufacturing facility for casting, achieving the integration of production and trade. Our prices and quality is superior to that of 90% of the suppliers in the market. We cut out the Precision castings and give our customers competitive prices, superior products and direct from our factory.