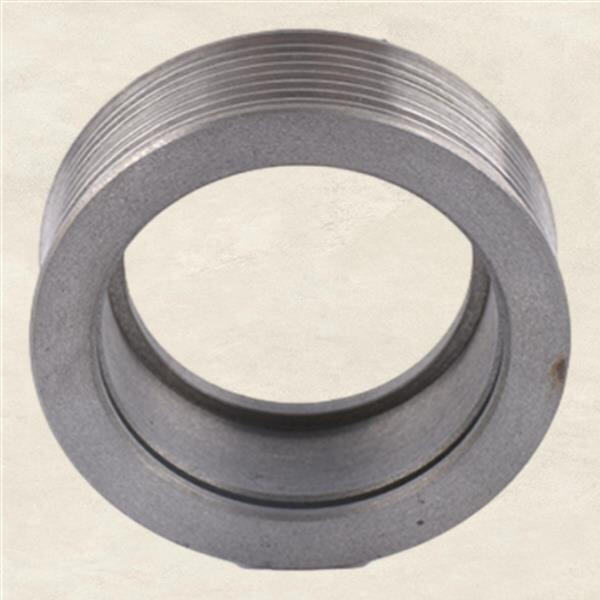

Grey iron casting is a very ancient method of metal manufacturing. It requires hot, molten iron to be poured into a choice of mold. This article will explain how grey iron casting works, why it is the best solution to make things, and where you can get it done.

Grey Iron Casting is the process used to create items from the type of iron that is softer and easier to work with than some of the other types. The first step consists of heating pieces of iron in a furnace until melting and becoming liquid. Then, the impure iron, why melted, is poured into "molds," that are in the shape of the item being created. The mold is then removed and the final product is set in place after the iron cools and hardens.

Grey Iron Casting A Good Option For Manufacturing Products One main reason is because it is very strong and long-lasting. Grey iron casting is used to manufacturer Items that can last for many year and in used. Grey iron casting is also versatile as it can manufacture a wide range of parts of different sizes and shapes. It is also an affordable method of production because the process is straightforward and does not require many expensive tools.

Pretend you want something made with grey iron casting, then the first thing you need to do is to know where to make it, its called as foundry. Factors you should consider when selecting a foundry include experience, quality, and prices. Lastly, it is even more important that you communicate well with the foundry about what you need so that can help you achieve your end goal.

In fact, grey iron casting has been around for thousands of years to produce tools, weapons, and machines. There have been gradual changes and improvements in the method of casting grey iron. The iron then gets turned into objects using new processes and tools that enable this. Grey iron casting is used in a variety of industries today, from cars to construction, and continues to be a prominent method of casting metal items.

We've served more than 100 customers who have customized their needs, offering rapid, precise and reliable customizing solutions. If you're looking for full customizing or grey iron casting foundry we are able to meet a variety of customer needs. Our experience and expertise ensure that every project we create is in line with the expectations of the customer.

We have automated production lines CNC machining centers and surface treatment grey iron casting foundry that work in tandem to provide technical assistance to support mass production We have the manufacturing capability to fulfill requirements of any size and still maintain production standards

We own our grey iron casting foundry factory, achieving the integration of production and trading. Our prices and quality are superior to 90% of the manufacturers in the market. Because we eliminate middlemen, we are able to offer competitive prices and better quality products directly from the factory to our clients.

Our 24-hour customer support team ensures that all inquiries are grey iron casting foundry answered quotes are given within 6 hours and custom solutions are made available within 12 hours No matter what time or location our customers call us we can promptly respond to them and provide professional services to ensure that their needs are addressed promptly