Grey cast iron is produced by melting iron and adding some other materials. It’s very durable and also never goes bad, which makes it good for many things. We encounter grey iron casting iron in car engines and in the pots and pans we use on our stovetops.

Grey cast iron Is very important in today’s world. It is used to produce a wide variety of parts to construct machines and tools. Car manufacturers, for instance, incorporate cast iron grey iron into engine blocks and brake components. It is also used to build buildings and bridges.

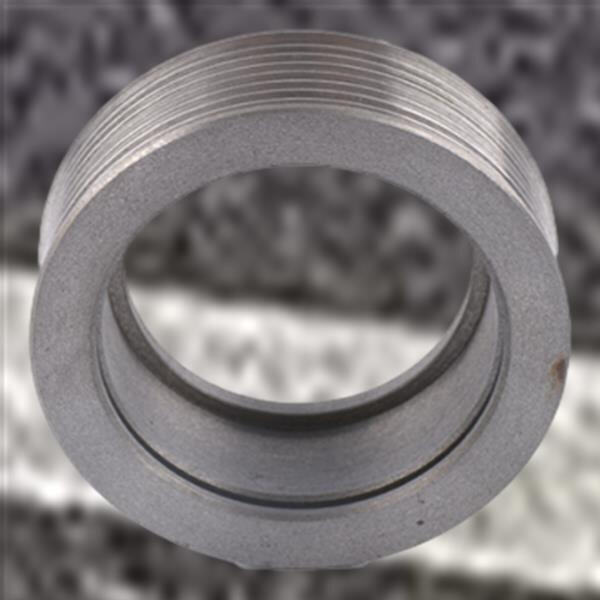

All this makes it great for industry: Grey cast iron with its many good qualities. It is incredibly tough and resistant to a great deal of stress. This is critical for components such gears and pulleys. It conducts heat well, too, which is helpful in certain areas where temperature is significant.

So there are many factors that are good when using grey cast iron in engineering issues. And it’s cheap and easy to work with, so many engineers like working with it. But there are some caveats as well. Grey cast iron doesn’t always stand up well for breaking and will break very easily if used the wrong way, so it’s important to stay away from it and opt for the right type of metal for the task at hand.

Maintaining your grey cast iron parts is the key to ensuring they have a long life. When not taken care of, this metal can rust and deteriorate. The grey cast iron has to be cleaned and treated on a regular basis. Following best-practice care guidelines, we can help to ensure that our grey cast iron parts continue to perform for years to come.