What Do You Think When you hear the word ''casting''? Against it, you may think of casting molten metal into a mold created from sand or clay. As it cools, the metal then firms up into a completed solid. There is this class of casting which in general terms is used for making artistic sculptures or ornaments, those that you find either at art galleries or around your home.

Grey Iron: A particular type of metal which is virtually indestructible. Developed by melting down in furnace the scrap iron, that is violated portion of press unwanted constituents. From there, the molten iron is mixed with other types of metals to create that perfect balance of just enough strength. This is then carefully poured into moulds, usually sand or other materials to form the desired shape.

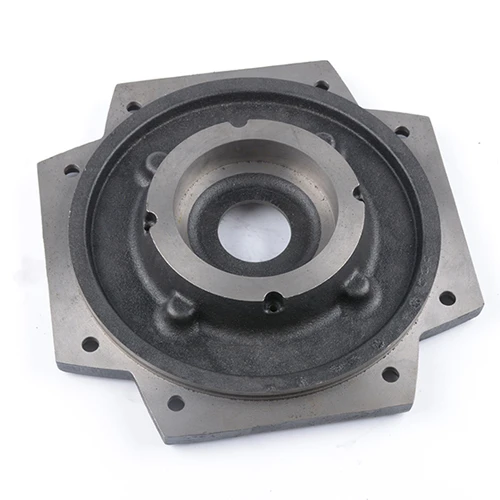

A grey iron casting factory is where learned workers relying on their knowledge of science, engineering, and art create molds to cast molten metal that hardens producing a quite high-quality finish. Once the castings are created, they go through a set of procedures where they have been cleaned and tested thoroughly in order to ensure that it is suitable for use at different levels.

Please note that not all grey iron castings are created equal. Safety should be your highest priority because, as you have already mentioned, some companies may use cheap materials or take shortcuts when casting - the result is a low-quality product. To ensure that you receive beautifully crafted and strong grey iron parts from the best manufacturers, it is important to buy them only if they are manufactured in a high-quality factory.

We invest not just in the latest equipment and technology but spend on R+ D solutions as well. Which means we end up w/ me usually looking at something to make our products even more awesome. This may be by experimenting with new materials or alloys, introducing some cutting-edge technology to boost our casting time but without compromising on the excellence we are known for.

When grey iron casting, precision and efficiency also play an important role. Every single part must be to the right specification, and it needs to fast as possible without any errors or delays. This is why we design each part first using computer-aided design (CAD) software, and produce a model for those parts long before the casting process ever gets underway. Thus, we avoid possible failures or differences from expectations in a early stage and optimize our work.

Our grey iron castings are the perfect solution for a wide variety of industries, whether you work in automotive agricultural or construction and require tough durable parts that can stand up to AdHocgrey particular environment. We are able to manufacture parts in probably the widest array of shapes and sizes, from small brackets right up to huge engine blocks. In fact, we are always up for the challenge to help customize designs or materials that may suit your needs.

We own grey iron casting manufacturer own casting facility which allows us to integrate production and trade. We have lower prices and better quality than the majority of our competitors. By eliminating the middleman, we offer more competitive prices and better quality products directly from factories for our customers.

Our production lines are automated grey iron casting manufacturer and surface treatment workshops that work together to provide technical support to support mass production Our manufacturing capabilities allow us to process orders from small quantities to large ones while maintaining the highest quality production standards and efficiency

Over grey iron casting manufacturer customers have been serviced by us, providing fast precise and efficient solutions. We are able to satisfy a wide array of requirements from customers whether they require total customization or design-based customization. Our knowledge and experience guarantee that every customized project will meet the client's expectations.

Our 24/7 customer service team ensures that all inquiries are responded to within one hour while quotes are issued within six hours and customized solutions are delivered in 12 hours Whatever time or place our customers call us to us we will respond promptly and provide grey iron casting manufacturer service ensuring their needs are met quickly