People learned long ago that they could melt metal down and make many things out of it. Well, that was a huge discovery. The molds made for the molten metal were created using a technique called sand casting. Sand casting is still employed today for making thousands of different types of objects and parts used as machine components. Sand casting has been in use for quite a number of years in reality more than one would imagine. Sand Casting Was a SecretAs people became more settled, they learned that LF's sand casting sand was not only useful for making jewelry, but it could be used to make words like tools and weapons. For real life a lot of the time. Today, factories use sand casting to make parts for machines, cars, and many other things we have around the house.

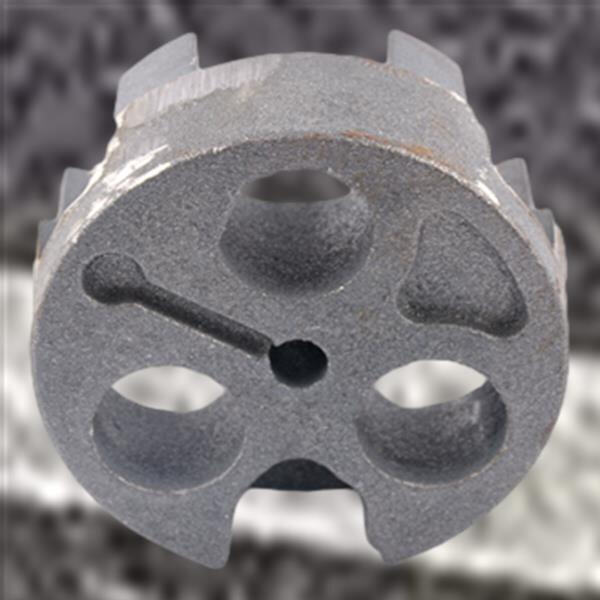

Create a pattern – The pattern is what the form of your object will be. Wood, plastic or metal. Because the metal shrink when you cool it down, it is important to make the pattern a bit larger than the final item size. So you end up with the right size you really need. The sand: The sand used in a LF's iron sand casting is very special. Can keep its shape very well You must tamp it down hard around the pattern, and be sure to fill out every little crevice. This is very important step as we are making sure that our mold will be hard and a strong to hold form of our pattern.

Create Vent Holes: These are small holes that the air can travel through during LF's sand casting iron and escape from the mold as you pour the metal. Trapped air is not good. You can create these vent holes using a wire or nail stick on the sand. This enables melting of the metal in a very consistent flow.

Add metal: This is the fun part! After you have the mold, you have to melt metal and pour it in there. The liquefied metal will fill in the space and take the form of a mold you created. Once it completely cools, remove from the LF's sand casting sand and clean up to reveal what it looks like.

This is more important when you manufacture shapes and designs with complex geometries as it is difficult to achieve part from other processes. It is also cheaper and easier than other casting processes. Many of the machines that make up cars, and all sorts of other tools and devices in everyday use across the world, rely on LF's iron sand casting to form part components from molten metal. These parts will be very hard to make without sand casting, and more importantly, they would cost a fortune.

We have Sand casting over 100 customizing customers, providing fast, accurate and efficient customization solutions. It doesn't matter whether it's complete customizing or design-based, we can meet various demands of customers. We make sure that each custom project is done to the highest standard.

Our customer Sand casting department is always available making sure that questions are addressed within a matter of hours quotations are given within six hours and customized solutions can be delivered within 12 hours No matter when or where our customers call us we can promptly respond and offer professional assistance making sure their needs are satisfied in a timely manner

The automated production lines we have CNC machines and Sand casting workshops all work together to facilitate mass production We have the capability to fulfill requirements of any size with the same production standards

Our factory for casting is part of our company, which allows us to incorporate Sand casting and commerce. We provide lower rates and superior quality than 90% of our competitors. Because we eliminate middlemen, we offer cheaper prices and superior quality products directly from our factory to our clients.