Back-breaking work, sculpting black sand is not. Designing these beautiful elements requires a lot of talent, creativity, and patience. In the beginning, one artist gathers black sand from places such as certain beaches and volcanoes which is a natural source for this type of sand. This is an important first step as to form beautiful sculptures you need the right type of sand. Once collected, the sand is then washed and dried to ensure it is free from impurities and is moisture-free

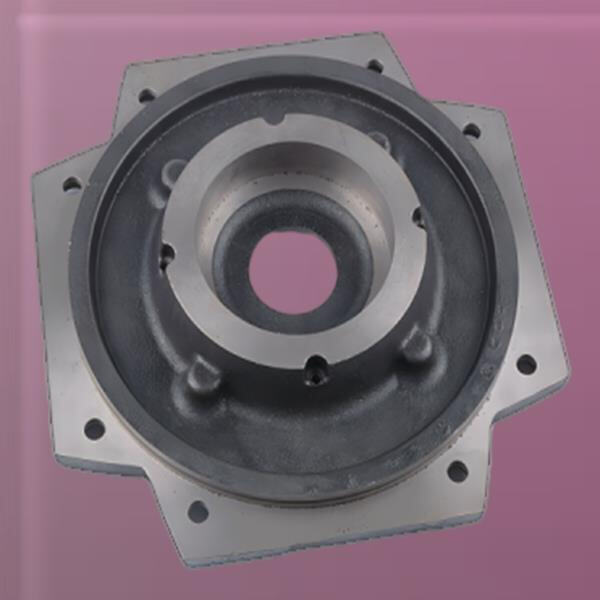

The sand once cleaned and thoroughly dried is blended with a binding agent. This could be a material like clay or resin which acts to bind the iron sand casting. The resulting mix is then packed into a mold, which is a kind of a cavity to give the stone the final shape of the sculpture. That could refer to a vase, a sculpture, or whatever the artist plans to create, and that would be the mold the artist hopes to create within. This aspect of the process is a point in which the artist displays their creativity, as the same process can yield many different shapes and sizes.

After that, one of the most important steps comes: filling the mold with hot, molten metal. This is a key moment, and the hot metal will take the shape of the sink. Then, the metal becomes cool and solid after some time. Once the metal has cooled down completely, the mold is broken apart to obtain the final sculpture. Depending on the size and complexity of the sculpture, this whole process may take hours or days to complete

Black sand casting is not only a technique, but also a form of art that looks classy and high-fashion. Each piece is beautifully contrasted with the distinct texture and dark hue of black sand casting foundry, making it truly one of a kind. From sculptures to decorative vases and even other kinds of objects, black sand casting adds an artistic and beautiful element to any home or office setting.

Our black sand casting pieces here at LF are meant to be unique and turn some heads. Using timeless artistry fused with modern designs, our talented artists and craftsmen create pieces that pay homage to the past while remaining relevant in contemporary times. Every piece is not just an aesthetic but also a functional piece that serves a dual purpose of being a piece of art as well. From classy vases to funky candleholders, each item is designed to seamlessly blend into each room or space.

The black sand casting also has an added advantage of different designs and sizes. Artist have a multitude of different options to customize the sand mold to their desire leading to never ending possibilities. Moreover, the sand casting iron provides a very attractive and unique texture and depth to the final work and such Adam objects or sculptures are literally one of a kind.

At LF one of our manufacturing methods is an old method of cast iron sand casting in black which allows to create both aesthetic and functional objects. At Craftsmanship Europe, the handcrafted production is our specialty, enabling us to deliver top-quality pieces that will serve the purpose, with the highest standards possible. We strive to make each piece not only a piece of art but also functional.

More than 100 customers have been helped by us, providing fast, accurate and effective solutions. We can meet a Black sand casting of client needs regardless of whether it's full customization or design-based customization. We make sure that every custom-designed project is executed in the most professional manner.

Our Black sand casting service department is available 24/7 assures that every inquiry is promptly answered and estimates are made within 6 hours and custom solutions are made available within 12 hours No matter when or where our customers reach out we can promptly respond and provide professional service ensuring their needs are met promptly

Our Black sand casting is part of our company, which allows us to integrate production and commerce. We can offer lower pricing and better quality than the majority of our competition. We cut out the middleman and give our customers competitive prices, higher quality products, and direct from the factory.

We have Black sand casting lines CNC machining centers and surface treatment workshops that collaborate to provide technical support for mass production Our manufacturing capabilities allow us to handle orders in large or small quantities while maintaining the highest quality production standards and efficiency