Contrairement à la plupart des métaux, la fonte grise est très unique fonderie en fonte nodulaire matériau. Il se compose de trois composants élémentaires qui incluent le fer, le carbone et le silicium. Lorsqu'ils sont combinés, ils forment un composé durci et durable avec de nombreuses caractéristiques excellentes. Bien que certaines personnes prétendent que le fonte grise est lourde et se casse facilement, il s'agit en réalité d'un matériau solide et durable qui intervient dans de nombreux produits.

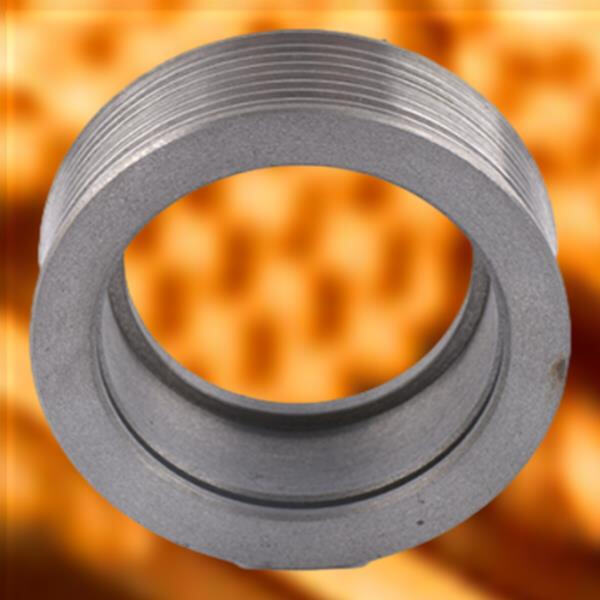

Elle présente une texture relativement unique qui peut être visuellement intéressante : le fonte grise contient des flocons de graphite dispersés, ce qui lui donne une couleur grise. Ces morceaux de graphite sont essentiels à la résistance supérieure du fonte grise à l'usure par rapport à de nombreux autres matériaux. Cela signifie qu'il peut être utilisé dans des zones qui pourraient potentiellement compromettre son intégrité. Le fonte grise agit également comme un bon matériau de transfert de chaleur. Sa polyvalence la rend assez utile dans de nombreux travaux et produits différents.

La fonte grise est largement utilisée dans de nombreuses industries pour diverses applications. La fonte grise est utilisée principalement pour les moteurs de voiture. Un moteur de voiture se compose de nombreux composants qui fonctionnent en harmonie pour faire fonctionner une voiture. La fonte grise n'est utilisée que dans les composants soumis à fortes contraintes, comme le bloc-moteur et les culasses de cylindres. Ces zones doivent être fabriquées avec des matériaux de grande résistance et durabilité pour résister à la chaleur et à la pression à l'intérieur du moteur, et la fonte grise fait exactement cela.

Il existe de nombreux avantages de l'utilisation de la fonte grise pour divers types de fonderies en fonte produits. Le principal avantage de celui-ci est qu'il est très solide ici. La fonte grise est conçue pour durer, elle peut résister à de fortes contraintes sans se fissurer. Elle est également résistante à l'usure, ce qui permet de la réutiliser dans tous les endroits où vous pourriez l'utiliser fréquemment. De plus, sa capacité à conduire la chaleur rend la fonte grise idéale pour des tâches nécessitant une résistance à la chaleur, comme dans les poêles ou les moteurs.

Cependant, la fonte grise présente également certains inconvénients. Un gros problème est qu'elle est fragile, donc elle se casse sous une pression ou des forces élevées. Par conséquent, il est crucial d'être prudent lors de l'utilisation ou du maniement des produits en fonte grise. L'autre pièces en fonte grise inconvénient est que la fonte grise est lourde, ce qui la rend difficile à soulever et à déplacer parfois. Le poids est encombrant à certains moments — il existe certainement des applications où vous pourriez utiliser un matériau plus léger.

La production de fonte grise est un processus complexe comportant plusieurs étapes. Tout commence avec les matières premières fonte grise des matériaux, tels que le fer, le carbone et le silicium, sont chauffés à une très haute température. Le processus de chauffage fait fondre les matériaux ensemble pour former un liquide. Les matériaux chauffés sont versés dans un moule (une forme spéciale dans laquelle ils se solidifient en refroidissant).

Si l'on examine attentivement l'historique de la technologie de production de fonte grise, on peut conclure que de nombreux changements passionnants et progrès ont eu lieu au fil des années. Le CAO et le FAO figurent parmi les développements technologiques plus modernes. De telles technologies aident les fabricants à produire des formes et éléments complexes et délicats. Cela signifie que les produits en fonte grise peuvent être coulés plus près les uns des autres pour des ajustements plus serrés et une meilleure efficacité.

Notre service client en fonte grise assure que toutes les demandes sont traitées dans l'heure, que les devis sont fournis dans les six heures et que des solutions personnalisées sont proposées dans les 12 heures. Nous sommes en mesure de répondre rapidement et efficacement à nos clients, quel que soit leur lieu d'implantation ou le mode de contact utilisé.

Les lignes de production automatisées que nous utilisons, y compris les machines CNC et les ateliers de fonte grise, travaillent ensemble pour faciliter la production en série. Nous avons la capacité de répondre à des exigences de toute taille avec les mêmes normes de production.

Nous possédons notre propre usine de fonderie pour la fonte grise, ce qui permet d'intégrer la production et le commerce. Nous pouvons offrir des prix plus bas et une qualité supérieure à 90 % de nos concurrents. En supprimant l'intermédiaire, nous proposons des prix plus compétitifs et des produits de meilleure qualité directement provenant des usines à nos clients.

Nous avons déjà accompagné plus de 100 clients sur mesure, en offrant des solutions de personnalisation rapides, précises et efficaces. Que vous recherchiez une personnalisation complète ou basée sur un design, nous pouvons satisfaire un large éventail de besoins du client en fonte grise. Nous veillons à ce que chaque projet sur mesure soit livré avec une qualité optimale.