Iron casting is this fabulous, adventurous technique of producing components of numerous objects that we see and use day by day. Iron is one of the oldest and the first metals people have used to make objects centuries ago! Why is it called "Casting"? Since the Iron is in a melted state it, gets poured into a particular shape called a Mold, then it cools down to that shape. Here at LF, we manufacture a wide variety of LF iron casting parts for constant supply to industries, so we thought you might want to know how that goes!

Casting iron parts is an art and science in itself! Melting the iron has to be done perfectly. Melting is one critical technology, for instance, were the iron not hot enough or too hot during melting, we would not get good casting when pouring it to the mold. Once melted, this liquid iron needs to be poured very carefully into the mold and to fill every little gap. Otherwise, the piece won't be right. That's why LF has a staff of experienced workers trained to melt the iron at the perfect temperature and pour it just the right way. This process of growing up makes for some very magical watching!

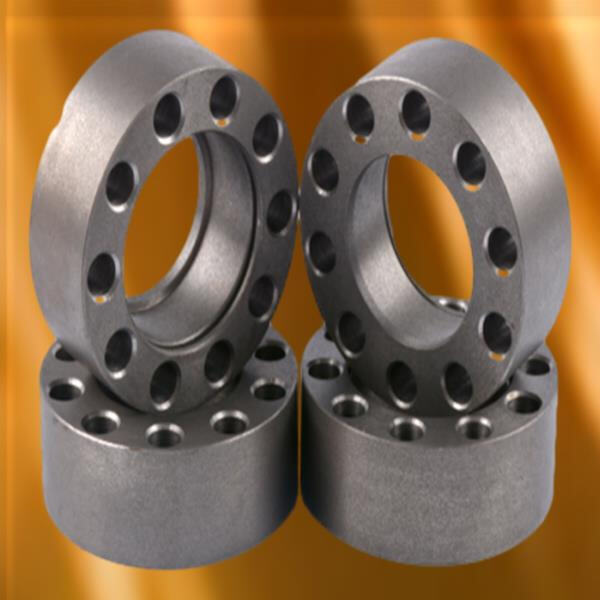

Why is making parts with iron casting advantageous? First of all, iron is a very hard metal. That means that the iron-based parts do not break or wear out after a lot of use. This is more critical when we are producing parts for items utilized highly, like cars, machinery or even tools. Another characteristic of iron casting is that it is very versatile, and because of that, we can manufacture many types of parts for many different industries. For instance, we can cast LF cast iron castings for the purpose of construction, automobile, or medical devices. Iron casting is also highly accurate so that it's possible to cast parts with perfect fitment. Now, this is very significant whenever we are actually building something huge; eg. a bridge, an apartment, for instance, the pieces have to be aligned in a perfect manner for it to be safe and operational.

LF has made the fussy job of iron casting out of the iron. So first, we made a mould of the part we want to make. This mould is basically a huge cup with the shape of the part inside it. Now that the mould is ready, we need to melt the iron. Now that it has melted into a liquid, we'll pour the liquid into the mould, making sure the cavity is wholly filled. When the iron cools, it hardens and the part becomes free from the mould. Other instances involve a little extra work you may have to do on the part after you take it out, as such: sand/polish/whatever to get the part to look nice and/or work. So, that's okay because the entire process is pretty fast, which allows us to make huge quantities of parts affordably!

The wonderful characteristics of cast iron make it one of the best materials to produce parts with! It is very solid and wear-proof, so the parts from LF cast iron casting will live years even in harsh conditions. Besides, cast iron is very easy to form and machine, that is why we may have many parts of different size and shape. It is a beautiful feature that is helpful over a wide variety of projects. Since cast iron is very precise, we can be sure that all the parts fit together every time. This is very essential, as particularly in a large construction, such as a machine or a bridge, since all these require accurate fitting to ensure safe and efficient functioning.

Thus, at LF, we can offer custom cast iron parts for any business. And we have made it for thousands of industries; automotive, construction, and military. Well, because iron casting is extremely versatile! Whether the parts we make are large, medium, small, or complex. All with exact specifications, that's all, all the parts can be manufactured just how you want them to be. Reach out to us if you need custom iron parts for your company! We will make you understand exactly what you want, and then we shall get on with getting you out a match made for you!

More than 100 customers have been helped by us, providing fast, accurate and effective solutions. We can meet a Iron casting part of client needs regardless of whether it's full customization or design-based customization. We make sure that every custom-designed project is executed in the most professional manner.

The casting plant we operate is owned by us, which enables us to combine production and Iron casting part. Our prices and quality are higher than 90% of the companies on the market. We eliminate the middleman and offer our customers more competitive prices, superior products and direct from the factory.

Our customer service department is available 24/7 Iron casting part that all queries are addressed within one hour while quotes are issued within six hours and customized solutions are offered within 12 hours We can respond promptly and professionally to our customers no matter which part of the world they are in or when they contact us

The automated production lines we have CNC machines and Iron casting part workshops all work together to facilitate mass production We have the capability to fulfill requirements of any size with the same production standards