This is a code that is made by melting together and the iron and pouring into the molds. They are extremely useful in various industries, so they are in high demand among manufacturers across the globe. From this text, we also will learn what are gray iron castings properties and advantages, its manufacturing process as well as quality checking process to ensure strength and durability. We will further discuss as to why using gray iron castings can be cost-efficient in the manufacturing process, particularly in heavy-duty jobs.

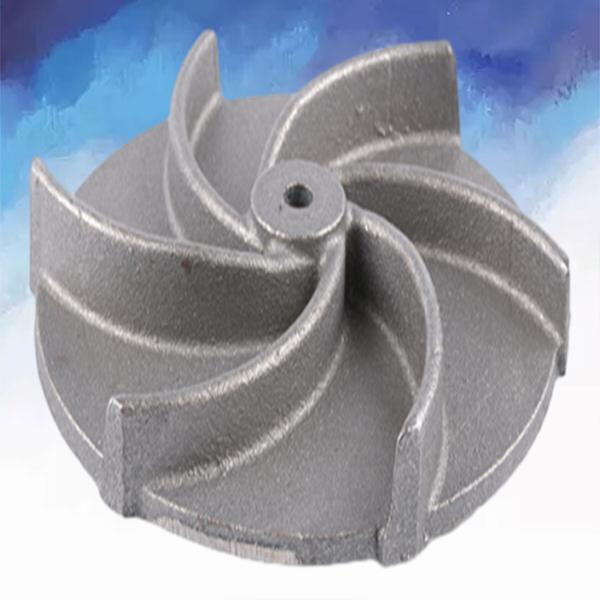

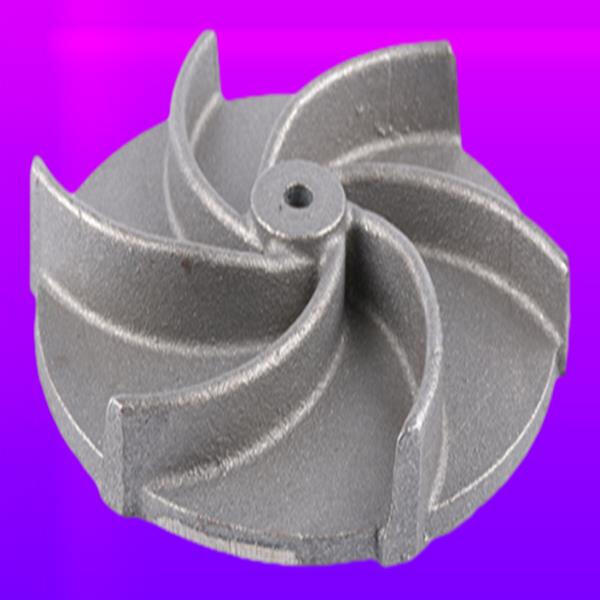

Gray iron castings can be used in a variety of industries, including automotive, construction, agriculture, and mining. They can be molded into various shapes and sizes, which makes them ideal for fabricating components that must be both durable and exact. A wide variety of tasks—from a gear for a tractor to a pump for cleaning water—can be put in gray iron castings, which can be tailored to meet the needs of any particular job.

Another very important property of gray iron castings is their strength and wear resistance. This makes them really good for stuff that requires high performance, such as machine parts and tools used in factories. Furthermore, gray iron castings are easy to work with, so they can achieve stringent specifications. This makes it easier for manufacturers to produce good-priced, high-quality parts.

Gray iron castings are produced by melting iron in a furnace. Once the iron reaches a liquid state, it is transferred into molds designed to acquire the required shape. Next, the molds are cooled to create solid chunks of metal. Checks are performed during the making process to test that the castings are strong, long-lasting, and the correct dimensions. Regular inspections and tests of both the materials used and the finished pieces also form part of this.

They are least expensive iron castings which are high-speed producing parts bothersome manufacturing. They are strong and very durable and thus serve for a very long time, thereby reducing the need to replace and repair them. Also, manufacturers can quickly produce complex parts as gray iron castings are easy to shape without any need for costly tools or machines.

Gray iron castings are so good that gray iron castings can be strong and long-lasting for some tough jobs. For example, gray iron castings show wonderful resistance to the tough working conditions in drilling with heavy rock bits, hydraulic machines, and other applications that involve high load and demanding environments and do not show any loss of performance under such conditions. Because of their wear resistance, they can handle abrasive materials and harsh environments, which makes them ideal for industries where strong and reliable components is a necessity.

We own gray iron castings own casting facility which allows us to integrate production and trade. We have lower prices and better quality than the majority of our competitors. By eliminating the middleman, we offer more competitive prices and better quality products directly from factories for our customers.

Our customer service department is available 24/7 ensuring that questions are addressed within 1 hour quotations are delivered within gray iron castings and solutions for customization can be delivered within 12 hours Whatever time or place our customers contact us they can be reached quickly and offer professional assistance making sure their needs are satisfied in a timely manner

Our production lines are automated CNC machining centers and surface treatment workshops that work together to provide technical assistance to support mass production We have the capability to meet gray iron castings of any size while maintaining production standards

We have gray iron castings over 100 customizing customers, providing fast, accurate and efficient customization solutions. It doesn't matter whether it's complete customizing or design-based, we can meet various demands of customers. We make sure that each custom project is done to the highest standard.