Have you ever stopped to wonder where cars, and buildings, and machines come from? Foundries are an enormous hot spot of data points. Foundries are places where materials like cast iron, and metal are smelted to produce shapes. These molds are then poured with melted grey cast iron casting materials that can be keep the shape, which is also called solidifies and cool. Foundries can be divided into two main subtypes: gray iron and ductile iron foundries. These foundries are essential in the manufacture of various everyday items that are needed every single day, including automobile parts, tools, and even some home appliances.

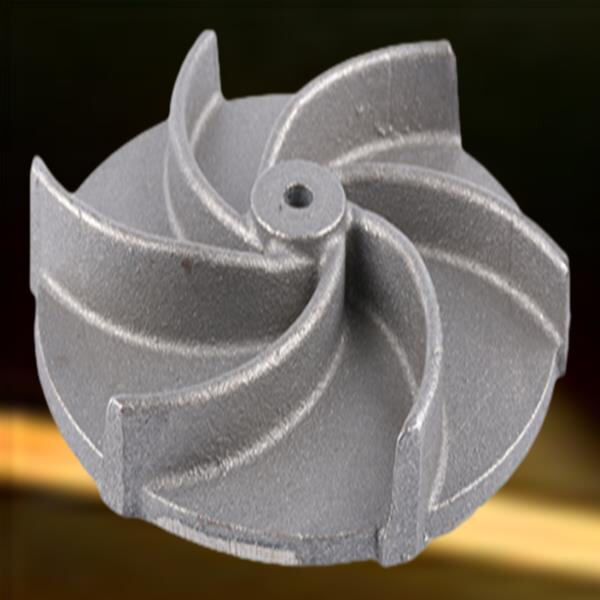

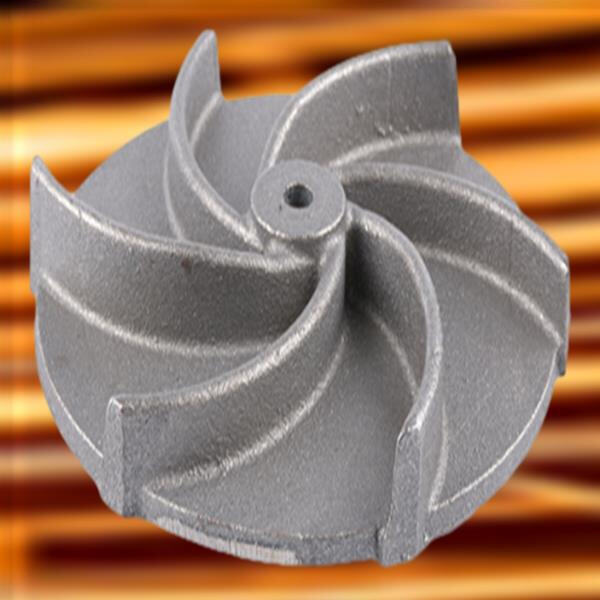

It is always one of the coolest places to see… where things that make other things happen. The Shaped grey iron casting products are prepared by melting iron in molten lava. Metal, iron (or metal of something else) is melted and poured into a form. Here the mold is made with a special sand that maintains the casting shape. It is also the reason why, when liquid iron is poured in to it, it moulds to its shape. Laden bar of iron pours, And off the cooling steel. once the casting is fully cooled then it is taken out of the mold. It is scrubbed and prepared for polish in order to manufacture a smooth end-product, ready to be issued for use in other areas of the cycle.

LF is constantly working with new technology in order to offer additional ways of delivering True-Value gray and ductile iron castings. Automatic Pouring – a cool way they do this In this process, liquid hot iron poured into the molds is done by robots. The robots enable LF to control the temperature of iron pouring so that it is constantly at the right temp. It will reduce the human-introduced error of hand pouring while producing a better casting. Not content to just cast, work has begun on computerized pouring from the LF and onto the planning board. And so then they can kind of test it before they even get started and make tweaks on the cast iron grey design side…to actually have a better finish product.

LF understands that environmental care in any form is well overdue from the foundries producing gray iron and ductile iron. They are even using energy conserving pieces of equipment so that the burden on Nature can be reduced, and also supporting back waste reduction moves. LF, for example, was already recycling more than 90 per cent of its water at the time when she explains. This means they reuse the same water, as opposed to TONS of disposable gallons of tap and or mineral. They have also installed a solar system. This provides a mean for them to extract the energy from the sun, which is a clean green and almost in-exhaustive source of energy. With this solar power, it will save them to use electricity from other resources that cause harm to the environment.

LF was the first to introduce new technology in order to maintain leadership in the foundry industry. They use latest tech – 3D printing In less time they are able to generate molds and set patterns and is worth for money as compare with the older approach where traditional molding was been used. In addition, LF also use the right ones, the latest of robotics applications where they are confident it will boost rates and productivity efficiency. It prevents the errors and oversights that might come from manual labor. With this advanced tech, LF offer the better castings to their customers and keep their competitiveness in the global market.

Our Gray and ductile iron foundries customer support Gray and ductile iron foundries assures that all queries are addressed within one hour quotes are given within six hours and customized solutions are provided within 12 hours We can respond promptly and efficiently to our clients regardless of where they are located or how they contact us

We have automated production lines CNC machining centers and surface treatment Gray and ductile iron foundries that work in tandem to provide technical assistance to support mass production We have the manufacturing capability to fulfill requirements of any size and still maintain production standards

More than 100 customers have been helped by us, providing fast, accurate and effective solutions. We can meet a Gray and ductile iron foundries of client needs regardless of whether it's full customization or design-based customization. We make sure that every custom-designed project is executed in the most professional manner.

Our factory for casting is part of our company, which allows us to incorporate Gray and ductile iron foundries and commerce. We provide lower rates and superior quality than 90% of our competitors. Because we eliminate middlemen, we offer cheaper prices and superior quality products directly from our factory to our clients.