Black casting sand is a unique type of sand, which is very beneficial for producing objects from metal. Black casting sand — black sand used for making metal stuff — will make better cast metal parts. So come and discover more about what makes black casting sand such a fantastic product that helps create shiny, fierce things!

Metal has to be melted and poured into a mold to take shape when metal is made. For that reason, black casting sand is used to allow the melted metal to flow freely inside the mold. It ensures that the metal parts come out clean and tidy. The black casting sand can also make the metal cool more stepwise, which makes it stronger and less likely to break.

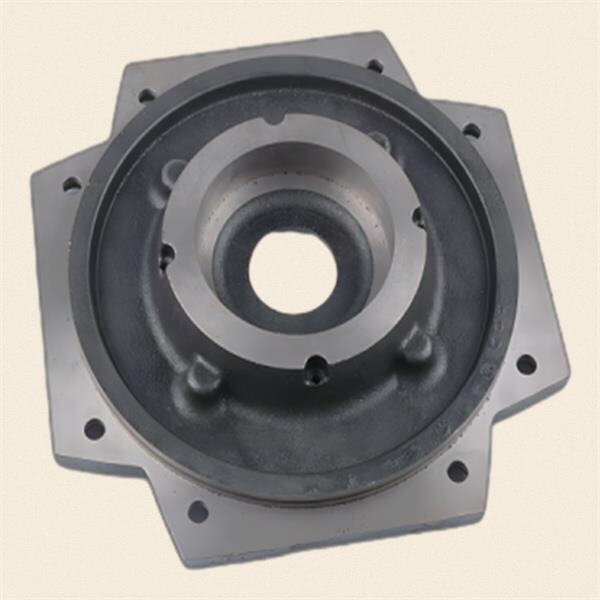

Casting metals in black sand makes shiny and smooth metal parts. This to help smooth any rough areas on the metal surface. Makes the metal parts appear polished and professional. The black casting sand also helps the metal pieces be more durable, so they last longer and operate better.

foundries: A foundry is a facility to melt metal and shape it into other materials. Foundries use black casting sand to create all metal things: car parts, tools, even sculptures. Its critical in metal making and get make sure every thing comes out on point.

This is why black casting sand should be handled carefully and stored properly. Black casting sand is abrasive, so use gloves and goggles to protect your skin and your eyes. Keep black casting sand stored somewhere dry, away from moisture that can cause it to clump together.

Metal-making with black casting sand may have environmental impact Used black casting sand must be disposed of properly so that air and water are kept clear. When possible, you should recycle black casting sand to maintain low waste pollution, protecting the planet's future.

Our customer service department is available 24/7 ensuring that questions are addressed within 1 hour quotations are delivered within black casting sand and solutions for customization can be delivered within 12 hours Whatever time or place our customers contact us they can be reached quickly and offer professional assistance making sure their needs are satisfied in a timely manner

black casting sand own our own manufacturing facility for casting, achieving the integration of production and trading. We can offer lower prices and higher quality than 90% of our competition. Through removing the middleman, we offer more competitive prices and superior quality products directly from factories for our customers.

Our production lines are automated, CNC machining centers, and surface treatment workshops that work together to provide technical assistance to support mass production. We have the capability to meet requirements of any black casting sand while maintaining production standards.

More than 100 customers have been helped by us, with fast efficient, precise and reliable solutions. No matter if it's full customization or design-based customization we are able to satisfy various requirements of our customers. Our experience and black casting sand ensure that every customized project will meet the requirements of the client.