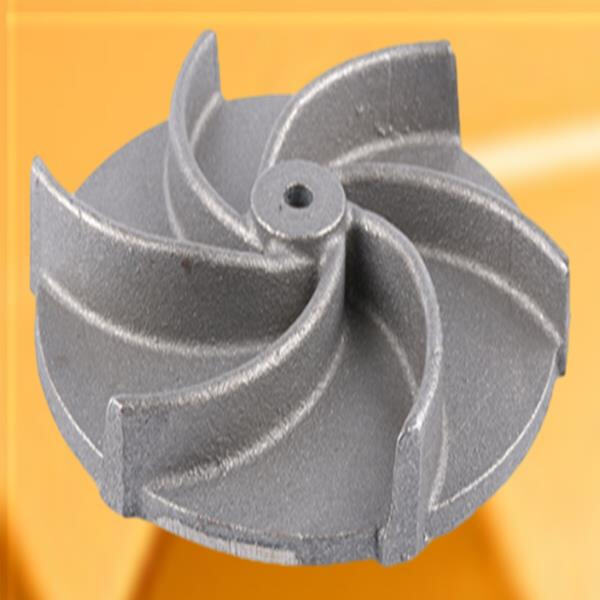

Gray cast is a type of metal that is widely used in construction and manufacturing. It is manufactured by smelting various metals together, including iron, carbon and silicon. It begins with these metals being heated till they melt down. The melted metal is then poured into a mold and given a shape. This mold guides the metal to take shape of the grey iron casting product being manufactured. Once the metal cools, it becomes grey cast. This is named "gray" due to its grayish color when it sets. Gray cast is strong and tough, making it perfect for many construction and manufacturing applications

A gray cast is metal around gray cast made with a method called casting. Casting is the process of melting metal or any material down and pouring it into a mold to shape it. Once the metal cools down, the gray material is left behind, and thus the name. This is a material well known for its durability. Gray cast is generally used in various products because of its high durability; for instance pipe and engine blocks and various machinery parts. Due to its high qualities with strong resistant property, it is widely used in many industries.

Gray cast can change in quality according to the grey cast iron casting materials that make it up and the presence of impurities. Impurities are unwanted substances that can find their way into the metal blend. Generally, the greater the proportion of carbon contained in the mixture, the harder the metal. In some applications, the right spectrum tends to make them prefer harder metal. But when it has too more Carbon, it can create a problem. Excess carbon can impart rapid cooling on the metal, resulting in cracks and other defects, for example. Hence the manufacturers needs to have the exact blend of materials in order to ensure that the gray has the right composition of components.

Cautions in Making gray cast Yes, cracks and holes (called porosity) are limited to the casting process problems at times. These problems render the cast iron grey metal weaker and turn it almost useless. However, the production of gray cast should be undertaken under specific rules and guidelines by the manufacturers to ensure that the result is robust and durable. While casting, close attention must be paid to temperatures and conditions to reduce these issues. If they are careful, they can produce only the best possible quality of gray cast.

Gray cast can be alloyed to increase its strength and toughness, for example, by adding magnesium and/or aluminum. This mixing of the iron sand casting metals is called alloying. This creates a new substance that has even more effective properties by combining two or more metals. For instance, magnesium will also increase strength and decrease brittleness in the gray cast. However, selecting the next metals to blend is of the most importance, The alloys chosen must be compatible with the base metal and improves its properties without introducing any undesired nuances.

It is imperative that manufacturers follow the guidelines and protocols as specified to ensure that gray cast is of the highest quality. This entails a clean and tidy workspace, good quality materials used and a very strict control of temperature in the casting place. Pouring molten metal into open molds is another point of attention needed by manufacturers in atmospheric control. By following these best practices, you can feel confident that your end product is solid and robust. Finally, safety is very relevant when it comes to handling materials at high temperatures. However, caution must always be exercised when dealing with hot, molten metal.

We own our own casting facility and have achieved the integration of production and trading. We offer better pricing and better quality than the majority of our Gray cast. We cut out the middleman and provide our customers with more price-competitive, high-quality products, and direct from the factory.

Over Gray cast customers have been serviced by us, providing fast precise and efficient solutions. We are able to satisfy a wide array of requirements from customers whether they require total customization or design-based customization. Our knowledge and experience guarantee that every customized project will meet the client's expectations.

Our customer service department is available 24/7 Gray cast that all queries are addressed within one hour while quotes are issued within six hours and customized solutions are offered within 12 hours We can respond promptly and professionally to our customers no matter which part of the world they are in or when they contact us

Our production lines are automated CNC machining centers and surface treatment workshops that work together to provide technical assistance to support mass production We have the capability to meet Gray cast of any size while maintaining production standards