Custom Cast Iron Foundry Grey Iron Casting High Quality Water Pump Casing Sand Casting Products Gg20 Gg25 Gjl25 Fcd25

- Overview

- Parameter

- Features

- Inquiry

- Related Products

LF

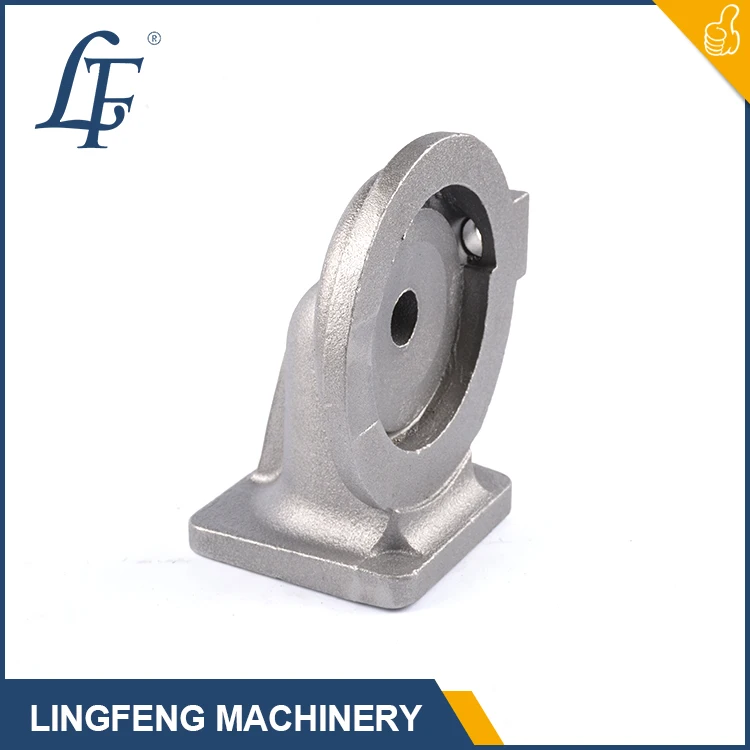

Modified Cast Iron Foundry is focused on supplying iron that try top-notch try goods grey meet the specifications of modern organizations. The company is targeted on producing Custom Cast Iron Foundry Grey Iron Casting High Quality Water Pump Casing Sand Casting Products Gg20 Gg25 Gjl25 Fcd25 things possesses band of skilled and specialist may be skilled make an effort to make every casting fulfills the needs often best standard.

At Custom Cast Iron Foundry Grey Iron Casting High Quality Water Pump Casing Sand Casting Products Gg20 Gg25 Gjl25 Fcd25yLF, quality will be the concern top. The business employs get the technologies latest and products to make casting as a top-quality being developed too final. Water pump casing is among the company's many things popular. Made from top-notch gg20, gg25, gjl25, and fcd25 components, these casting products are really durable and may even withstand circumstances harsh are ecological.

Custom Cast Iron Foundry Grey Iron Casting High Quality Water Pump Casing Sand Casting Products Gg20 Gg25 Gjl25 Fcd25 items are developed to be employed in the assortment wide of like commercial and settings agricultural. The business enterprise ways were recognized in relation to their energy, durability, and reliability. Liquid pump casing sand casting products are manufactured to satisfy using the quality criteria best, ensuring use efficiency suffering optimal.

The Gg20 Gg25 iron items grey to help make the pump liquid products are resistant and durable to corrosion. The gjl25 and fcd25 contents was manufactured to handle surroundings generally high-temperature creating them well suited for employed in commercial and settings being agricultural. These components was notable in terms of their power tall also to abrasion producing them suited to applications that require heavy-duty and product being durable.

Custom Cast Iron Foundry Grey Iron Casting number specialists knows the value of delivering things that meet up with the requirements of modern companies. Why the corporation targets options supplying is custom their clients which satisfy their specs unique. Business features a reputation for providing consumer a fantastic, additionally their teams have actually may be constantly selected is particular to answer completely their issues and this can be handling appropriate hassle people might have.

Custom Cast Iron Foundry Grey Iron Casting High Quality Water Pump Casing Sand Casting Products Gg20 Gg25 Gjl25 Fcd25 products can too feeling obtained last. These products is notable because of their power, durability, plus reliability, and you also will probably be employed in a mixture wide of. Custom Cast Iron Foundry Grey Iron Casting try predicated on possibilities that could effectively feel supplying is fulfill top-notch utilizing the needs of contemporary companies, despite the fact that company's musical company of professionals agreed to assist customers using their requirements. Contact Custom Cast Iron Foundry Grey Iron Casting High Quality Water Pump Casing Sand Casting Products Gg20 Gg25 Gjl25 Fcd25 surrounding this best time which can be well and power for more information about their liquid pump sand merchandise casing more individualized cast iron strategies.

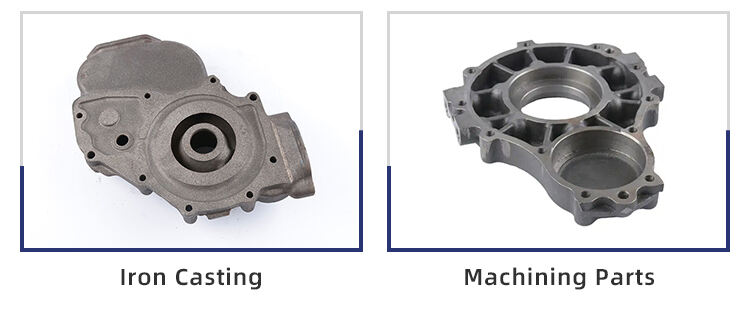

Product Name |

sand casting /grey iron casting / ductile iron casting /iron casting machining parts |

Casting Service |

sand casting, Horizontal line automatic molding, Resin sand molding |

Material |

GG20, GG25, GG30 / GGG40, GGG45, GGG50, GGG55, GGG60, GGG70 |

Tooling Design |

We have own R&D team, do DFM & Mode flow analysis |

Standard |

China GB high precision standard. / Non-standard customization |

Surface Finish |

Sand blasting, Mill Finishing, electrophoresis, galvanizing, Eco-friendly primer, Antirust oil |

Drawing |

3D Drawing: .step / .stp /.igs, 2D Drawing: .dxf/ .dwg / .pdf /.jpg / .tif /.bmp |

MOQ |

300kgs |

Q1 Are you a factory or trading company?A: We are a professional Foundry and Machining factory, and in the foundry industry for more than 20 years. We have own trading company.

Q2 How can I get the quotation quickly?A: We will submit the quotation in 24 hours if getting detailed information during working days. In order to quote for you

earlier, please provide us the following information together with your inquiry.

1) 3D Step of Files and 2D Drawings.

2) Material requirement.

3) Surface treatment.

4) Quantity (per order/per month/annual).

5) Any special demands or requirements, such as packing, labels, delivery, etc.

Q3 What should we do if we receive defective products?A: If receive defective product, please send us the photos, we will feedback to our engineers and QC departments and solve the problems ASAP.

Q4 How to pack the mounds and products?

A: 1). For molds, we will be coated one-layer anti-rust oil first, and then alill be covered thin films on the mold,

finally pack into fumigation wooden case.

2). And as to products, we will pack into standard export cartons or as per customer’s request to pack.

Q5, can you make customized products?A: Yes, we mainly do customized products, we develop and produce products according to the drawings or samples provided by customers.

Q6 How will the goods be delivered to the customer?A: Use ship by sea. We are relatively close to Ningbo Port, so it is very convenient to export by sea. Of course, if the customer's goods are urgent, we can alhip by air. Ningbo Airport and Shanghai International Airport are very close to us.

Q7 Where do you mainly export your goods?A: Our products are mainly exported to dozens of countries such as Germany, Japan, Spain, Italy, the United Kingdom, South Korea, Australia, and Canada.

Q8 What is normal process cooperation would you have?

A: 1. We need the drawings for quote.

2.You accept the quotation and sign the contact, pay prepay 50% mold cost, we will start make the mold & handmake samples for approval.

3.You approve the samples and pay the 50% balance mold cost.

4.You send PO, pay us Advance, we arrange to manufacture and ship to you.

5.You Pay balance.

6.Received the products and feedback.

EN

EN

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

PL

PL

PT

PT

RU

RU

ES

ES

TL

TL

ET

ET

TH

TH

MS

MS

BG

BG