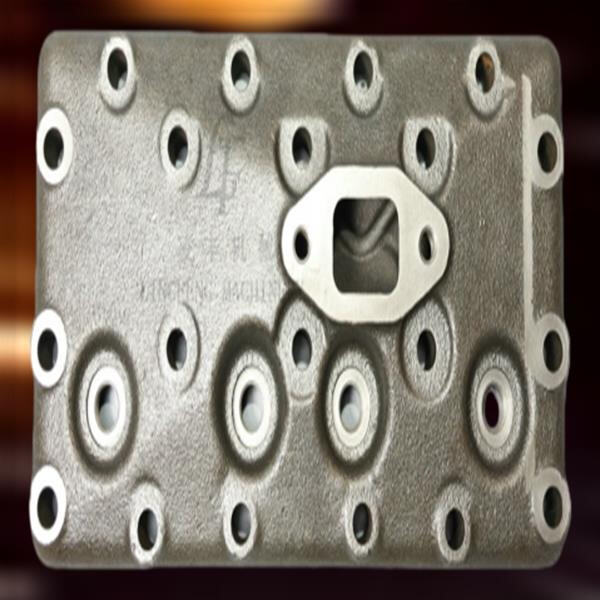

Vous avez un problème avec votre collecteur en fonte sur votre voiture. Ne vous inquiétez pas, laissez l'entreprise LF s'occuper de tous vos besoins en soudure. Le collecteur en fonte, une rupture et/ou déchirure occasionnelle d'un composant essentiel de votre voiture. La fonte est un métal difficile à souder et ces conseils vous aideront à le réparer, en utilisant de la fonte grise selon le besoin. Voici simplement quelques étapes pour vous guider dans le processus de soudage de votre collecteur. Nettoyez bien le collecteur.

Réchauffez le collecteur. La fonte ne chauffe pas comme les autres métaux. Le chauffage de la zone soudrée à l'arrière empêchera la fissuration. Il est plus facile à souder et permet souvent une meilleure liaison lorsque le métal est chaud. Avant de commencer à souder des pièces en fonte grises, vous pouvez chauffer le collecteur avec une torche ou une couverture chauffante.

Utilisez la bonne tige de soudage. Une tige de soudage pour la fonte: c'est super d'aller avec la bonne. Il faut une sorte de tige, qui est généralement en nickel. Plus agressif et beaucoup plus souple que les barres habituelles en nickel, le fait d'être soudé avec la bonne barre garantit qu'il ne se casse pas sous tension une fois monté sur une voiture, ce qui est très important pour la sécurité et les performances.

Ceci est absolument essentiel car le nettoyage du collecteur avant le soudage est très critique. Prenez un peu de temps pour enlever la rouille, la saleté ou le vieux grais de la zone où vous allez souder. Le nettoyage est également crucial car il prépare le collecteur au nouveau métal qui s'unit relativement plus facilement. Si la surface est sale, la soudure ne tiendra pas correctement et cela causera plus de problèmes plus tard.

Définissez une faible intensité amperométrique. Le soudeur produit de la chaleur en fonction du niveau d'intensité que vous avez défini sur votre appareil. Le fonte, par ailleurs, est un matériau fragile - cela signifie que si elle surchauffe, il y a un risque qu'elle se fissure. Donc, lorsque vous soudez, vous devez avoir une faible intensité, de cette manière tout dommage possible et toute fissuration sera évitée dans la fonte.

Préparez le nouveau métal. Ensuite, il vous faut un morceau de métal neuf, d'une épaisseur identique à celle de votre collecteur. Prenez un petit morceau et faites des découpes au bon endroit. Cette nouvelle pièce doit être propre et exempte de corrosion ou de saleté. Comme c'était le cas avec le collecteur, le bruit sera à basse pression. prix de la fonte , si le métal neuf n'est pas propre, cela pourrait poser problème pour la soudure.

Installez le nouveau métal. Maintenant que tout ce métal neuf est préparé, il est temps de l'installer sur le collecteur en utilisant votre soudeuse. Pour fixer provisoirement la nouvelle pièce contre le collecteur, utilisez un réglage à faible intensité sur votre soudeuse. Pensez à la fixation comme une série de petites soudes pour positionner le nouveau métal à l'endroit où il doit aller. La raison en est que le métal nouvellement ajouté bougerait pendant que vous terminez la soudure.

Nos lignes de production sont automatisées : les ateliers de soudage des collecteurs en fonte et de traitement de surface travaillent ensemble pour fournir un support technique destiné à soutenir la production de masse. Nos capacités de fabrication nous permettent de traiter des commandes allant de petites à grandes quantités, tout en maintenant les normes de qualité et d'efficacité les plus élevées.

Nous avons déjà servi plus de clients pour le soudage de collecteurs en fonte, en proposant des solutions rapides, précises et efficaces. Nous sommes en mesure de satisfaire une grande variété de besoins, qu'il s'agisse de personnalisation totale ou de personnalisation selon un modèle existant. Notre savoir-faire et notre expérience garantissent que chaque projet sur mesure répondra aux attentes du client.

Nous possédons notre propre usine de fonderie de collecteurs de soudage, ce qui nous permet d'intégrer la production et le commerce. Nous proposons des prix inférieurs et une meilleure qualité que la majorité de nos concurrents. En éliminant l'intermédiaire, nous offrons des prix plus compétitifs et des produits de meilleure qualité directement depuis les usines pour nos clients.

Notre équipe de service client est toujours disponible et veille à ce que les demandes soient traitées en quelques heures, que les devis soient envoyés sous 6 heures et que des solutions personnalisées puissent être fournies dans les délais requis. Quel que soit le moment ou le lieu où nos clients nous contactent, nous répondrons rapidement et offrirons une assistance professionnelle afin de satisfaire leurs besoins au plus vite.