Car en fabriquant les objets et les outils utilisés également pour les machines, LF fonderie de fonte grise est un matériau essentiel pour cela. Il est solide, robuste et fiable, c'est pourquoi nous pensons qu'il convient parfaitement à un usage industriel.

Les avantages de la fonte grise GG20 dans l'industrie Comprendre pourquoi elle est considérée comme telle peut nous aider à comprendre pourquoi elle est l'un des matériaux les plus recherchés de notre époque : elle est appréciée pour sa capacité à résister à des températures élevées et à des charges importantes, ce qui la rend utile pour des applications telles que les blocs-moteurs et les tuyaux. Elle est également plus économique, ce qui peut entraîner des économies de coûts pour les entreprises souhaitant produire des produits de qualité à moindre coût.

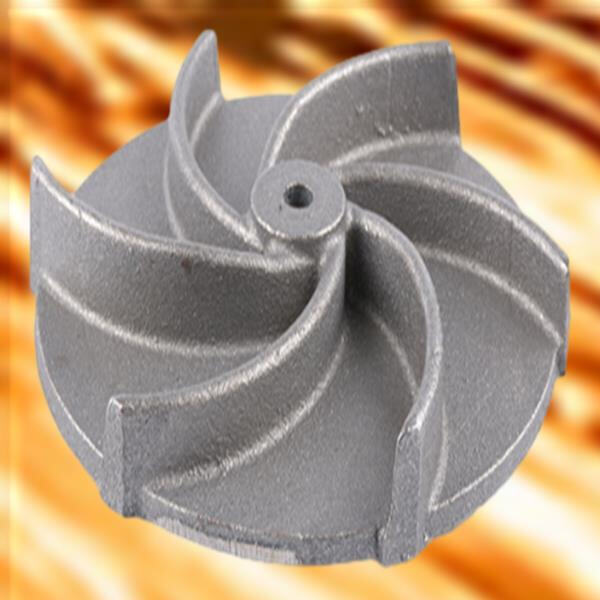

Les qualités durables de la fonte grise GG20 en font une option idéale pour une grande variété de produits. Elle peut être transformée en tout, allant de pièces automobiles à des casseroles, puisqu'elle peut être moulée en diverses formes. Cela signifie que l'entreprise peut proposer des produits innovants qui sont durables et fiables — lui permettant de se démarquer dans un domaine concurrentiel.

Comprendre les détails du processus de moulage en fonte grise GG20 aidera à expliquer pourquoi il est inestimable lors de la création d'un produit. Le processus commence par la fusion du fer et son coulage dans un moule, qui refroidit et durcit pour prendre la forme désirée. LF fonderies en fonte précision signifie que les produits sont créés avec une taille précise et un aspect professionnel.

C'est la haute résistance et sa bonne conductivité thermique de LF moulage en fonte grise qui font qu'il fonctionne si bien. Sa durabilité permet son utilisation dans des conditions difficiles, sa stabilité empêche les produits de se déformer sous l'effet de la chaleur, et sa conductivité thermique aide à refroidir les produits même en cas de chaleur extrême. Cela signifie que les produits de fonderie en fonte grise gg20 sont non seulement durables, mais également efficaces en termes de performance.

Le rôle de la fonte grise gg20 dans l'industrie manufacturière moderne est quelque chose qui ne peut absolument pas être ignoré. Sans elle, les entreprises auraient du mal à produire les biens dont nous dépendons quotidiennement. Des véhicules aux appareils électriques, LF pièces en fonte grise se retrouve dans beaucoup de nos produits préférés, contribuant ainsi à la croissance globale de l'industrie manufacturière.

Nous possédons une fonderie de fonte grise GG20, ce qui nous permet d'intégrer la production et le commerce. Nous proposons des prix inférieurs et une qualité supérieure à la majorité de nos concurrents. En éliminant l'intermédiaire, nous offrons à nos clients des prix plus compétitifs et des produits de meilleure qualité directement issues des usines.

Notre service clientèle est disponible 24/7, s'assurant que les questions sont traitées dans un délai d'une heure, que les devis sont livrés dans le Gray iron casting gg20 et que des solutions pour la personnalisation peuvent être fournies dans un délai de 12 heures. Peu importe l'heure ou l'endroit où nos clients nous contactent, ils peuvent être rapidement joints et obtenir une assistance professionnelle, en s'assurant que leurs besoins soient satisfaits dans les délais.

Nos lignes de production automatisées, nos machines CNC et nos ateliers de coulée de fonte grise GG20 fonctionnent tous en synergie pour faciliter la production de masse. Nous sommes capables de répondre à des exigences de toute taille, tout en respectant les mêmes normes de production.

Nous avons déjà aidé plus de 100 clients, avec rapidité, précision et des pièces moulées en fonte grise GG20. Si vous recherchez une personnalisation complète ou une personnalisation basée sur un design, nous sommes en mesure de satisfaire une grande variété de besoins clients. Notre expertise et notre expérience garantissent que chaque projet personnalisé répondra aux exigences du client.