Le fer est un métal très solide. Si solide qu'il peut se plier et s'étirer sans se casser. C'est cette capacité extraordinaire qui rend les fonderies d'acier ductile si vitales pour notre planète. Ces fonderies produisent et fabriquent une multitude de choses que nous utilisons dans notre vie quotidienne, comme les tuyaux utilisés pour transporter de l'eau, les engrenages utilisés pour le mouvement des machines, et même des pièces de voitures et d'avions qui facilitent nos déplacements.

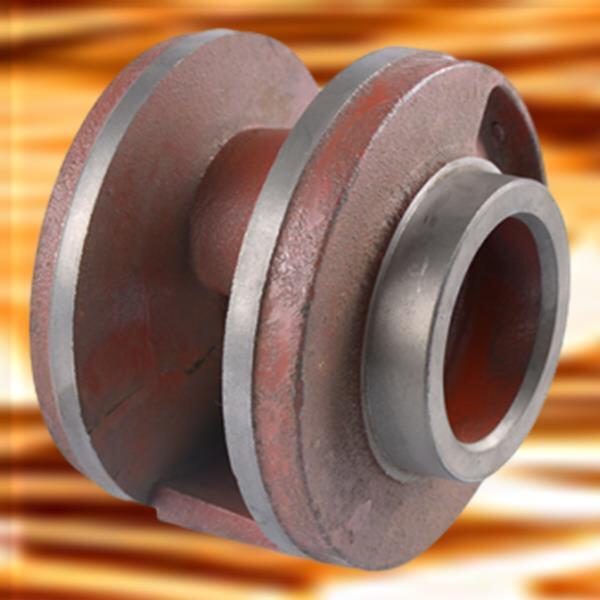

Une forme spéciale de fer est le fonte ductile. Elle n'est pas seulement forte, mais aussi plus flexible que la fonte traditionnelle. Cela indique maintenant qu'elle est incroyablement bien conçue et qu'elle résiste même sous une pression extrême. La fonte ductile peut être liquéfiée grâce à un procédé de fusion approprié. Elle peut ensuite être versée dans un moule pour former une grande variété de formes, comme des blocs-moteurs pour maintenir les voitures en fonctionnement ou de grandes canalisations utilisées dans les bâtiments et les usines. Les fonderies de fonte ductile mettent beaucoup d'efforts pour s'assurer que les produits fabriqués sont non seulement durables, mais aussi long-lasting. Pourquoi cela poserait-il problème : Eh bien, bien sûr, nous voulons des produits sûrs et fiables sur lesquels nous pouvons compter. fonte sur mesure produits dont nous pouvons nous fier.

Pour rendre chaque pièce parfaite, les fonderies d'acier ductile utilisent des techniques spéciales. Elles passent un temps supplémentaire à fabriquer les moules nécessaires exactement dans le cas de chaque produit. Elles s'assurent avec soin que les pièces du puzzle s'emboîtent bien et fonctionnent comme prévu. Elles garantissent des produits de qualité en vérifiant leurs produits et en utilisant des méthodes précises pour s'assurer que le client reçoit le produit parfait qui répond à ses besoins.

Les fonderies d'acier ductile sont toujours à la recherche de pratiques récentes pour travailler efficacement et rester en avance sur les autres fonderies. Elles possèdent des ordinateurs, qui sont utilisés pour créer des formes uniques adaptées à chaque projet. Avec cette technologie, elles peuvent réaliser des conceptions qui seraient difficiles à créer à la main. De même, des robots sont également utilisés pour verser le métal fondu fonte grise dans les moules. Elles utilisent des robots pour s'assurer qu'elles peuvent contrôler la température et la pression avec une grande précision. Cela signifie qu'elles sont très précises dans chaque produit créé et maintiennent un niveau de qualité très élevé.

Les fonderies d'acier ductile s'inquiètent également des ressources terrestres. Elles recyclent également la ferraille, qui correspond à toutes les pièces restantes d'autres projets. Cette ferraille fonte grise peut être fondue et réutilisée, minimisant ainsi les déchets. De plus, elles prennent grand soin de se débarrasser des matériaux de déchet. Elles le font de manière responsable — de telle sorte qu'il n'y ait aucun impact sur l'environnement. De plus, ces fonderies utilisent des technologies innovantes pour économiser l'énergie et réduire la pollution, ce qui est bénéfique pour tous.

L'un des aspects intéressants des fonderies d'acier ductile est leur capacité à adapter les produits aux spécifications uniques de chaque client. Elles collaborent avec les clients pour choisir les conceptions, matériaux et finitions appropriés pour leurs projets. Cela permet aux clients d'obtenir exactement les pièces dont ils ont besoin pour leurs projets spéciaux et rend leur travail plus simple et efficace.

Plus de 100 clients ont été accompagnés par nos soins, grâce à des solutions rapides, efficaces, précises et fiables. Que ce soit une personnalisation complète ou une personnalisation basée sur le design, nous sommes en mesure de satisfaire divers besoins de nos clients. Notre expérience et nos fonderies de fonte ductile garantissent que chaque projet personnalisé répondra aux exigences du client.

Nos lignes de production automatisées, machines CNC et ateliers de traitement de surface fonctionnent en synergie pour soutenir les fonderies de fonte ductile. Nous disposons de capacités de fabrication permettant de répondre à des demandes de toute taille, tout en conservant les mêmes normes de production.

L'usine de fonderie que nous exploitons est notre propre propriété, ce qui nous permet d'intégrer la production et les fonderies de fonte ductile. Nos prix et notre qualité sont supérieurs à ceux de 90 % des entreprises présentes sur le marché. Nous éliminons l'intermédiaire et proposons à nos clients des prix plus compétitifs, des produits supérieurs et une livraison directe usine.

Notre équipe de service client disponible 24/7 assure que toutes les demandes sont traitées rapidement, que des devis sont fournis par des fonderies de fonte ductile et que des solutions personnalisées sont proposées dans les 12 heures. Quel que soit le moment ou l'endroit où nos clients nous contactent, nous sommes en mesure de répondre rapidement et d'offrir une assistance professionnelle afin que leurs besoins soient satisfaits sans délai