Harman valkoinen teräs on erityinen materiaali, jota käytetään moniin tarkoituksiin. Se rakennetaan epätyypillisellä tavalla ja sillä on joitakin mielenkiintoisia ominaisuuksia. Otetaanpa lähemmäksi tutustumaan harpinmaisen raudan tuottaminen ja sen paikka maailmassa!

Harman valkoisen teräksen valmistus tapahtuu hymyttämällä rautaa ja sekoittamalla sitä muihin alkioihin, kuten hiiliin ja silioniin. Sekoitus vedetään sitten muovien sisään ja jäädytetään. Harman valkoisen teräksen hauskaa piirrettä on se, että se sisältää pieniä määriä grafiittia, mikä tekee sen harmaaksi.

Harmaa muovilehti on sekä vahva että kestävä, mikä tekee siitä ideaalin monen teollisuuden alan valintaa. Se on myös helppo muokata erilaisiin muotoihin. Toinen hyvä puoli on sen kestokyky, joten sitä voidaan käyttää pitkään ilman, että se hajottuu.

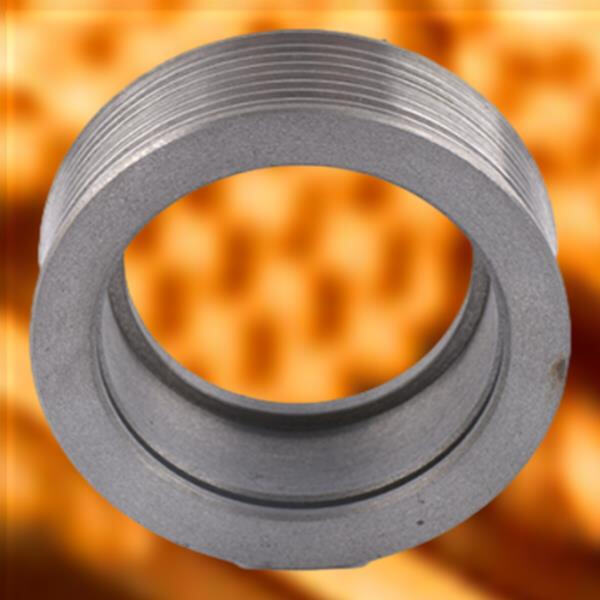

Harmaa muovilehti löytyy monista paikoista, kuten auton korkeista, rakennuksista ja tehtaista. Autoalan yhteydessä sitä käytetään moottoripohjoihin ja jarrulevyn talviin. Rakennusalalla: Sitä käytetään putkien ja sovitusten valmistukseen. Teollisuudessa se käytetään koneistossa ja työkaluissa.

On mukavaa ainakin omaksua harmaa muovinkivi mestarikoru sen ansioluetteloon kuuluu, että haramaa muovilehteä on helppo ja halpaa tuottaa. Se on myös todella vahva. Mutta se voi olla painava – mikä tekee sen kuljetuksen vaativaksi. Toinen haittapuoli on, että se on herkkä ja hajos nopee, jos sitä ei käsitellä huolellisesti.

Siksi tulevaisuudessa monet eri sektorit jatkavat harmaan valkoisen teräksen käyttöä. Mutta kun teknologia kehittyy, voidaan suunnitella uusia materiaaleja, jotka ovat kevyempiä ja vahvempia. Silti harmaa valkoinen teräs ei ole menossa menemään vanhentuneeksi; siinä on erityisiä ominaisuuksia ja niin hyödyllistä, että sen tulisi olla mielessä.

Meidän 24/7 asiakaspalvelutiimi varmistaa, että kaikki kysymykset saavat nopean vastauksen, tarjoukset annetaan valurautapohjaisille tuotteille ja mukautetut ratkaisut toimitetaan 12 tunnissa. Asiakkaamme voivat ottaa meihin yhteyttä milloin tahansa ja mistä tahansa, ja me pystymme vastaamaan nopeasti sekä tarjoamaan ammattimaisen tuen, jotta heidän tarpeensa voidaan hoitaa viipymättä.

Meidän automatisoidut tuotantolinjat, CNC-koneet ja pinnankäsittelyteollisuuden työpajat toimivat yhteistyössä valurautapohjaisten tuotteiden tukemiseksi. Meillä on valmistuskykyä täyttää kaiken kokoiset vaatimukset samalla tuotantostandardilla.

Meillä on oma valimo, ja olemme saavuttaneet tuotannon ja kaupan integroinnin. Tarjoamme parempia hintoja ja parempaa laatua kuin suurin osa valurautapohjaisten tuotteiden toimittajista. Poistamme välittäjän ja tarjoamme asiakkaillemme kilpailukykyisempiä, korkealaatuisia tuotteita suoraan tehtaalta.

Olemme palvelleet yli 100 asiakasta nopeilla, tarkoilla ja tehokkailla ratkaisuilla. Voimme täyttää laajan kirjon asiakastarpeita, mukaan lukien täydellinen räätälöinti tai suunnitteluperusteinen räätälöinti. Asiantuntemuksemme ja kokemuksemme varmistavat, että jokainen luomamme projekti vastaa valurauta GJL-tyyppisen (harmaan valuraudan) vaatimuksia.