Производителите на литейни модели разполагат с редица ключови инструменти и материали за създаване на модели за леене на метали. Това включва създаването на модели с тези материали, които след това се използват за изграждане на форми за отливане на метални части. В LF разполагаме с множество висококачествени материали, така че производителите на модели да могат да създават своите най-добри модели за проектите си.

Дъската за модели е важно работно средство за моделарите. Това е равна дъска, върху която могат да изработват модела с инструменти като гравирни ножове, длета и шкурка. Следващата стъпка е да се осигури правилната форма и дизайн на модела чрез дъската за модели.

Hi-mold кафез. Друг важен инструмент е формовът кафез. Той е контейнер с формата на кутия, който задържа модела на място по време на изработване на формата. Формовите кафези се предлагат в различни форми, за да отговарят на различните модели.

Добри материали са необходими за производството на точни модели за леене на метал. LF разполага с всички видове материали, като например моделираща глина, пясък, смола. Моделът се оформя от моделираща глина, а пясъкът и смолата се използват за изработване на формата за леене.

Има някои специални материали, които също са важни за изработването на модели. Това включва восък и силиконова гума. Восъкът се използва за детайлиране на модела, а силиконовата гума позволява изработването на гъвкави и многократно използвани форми.

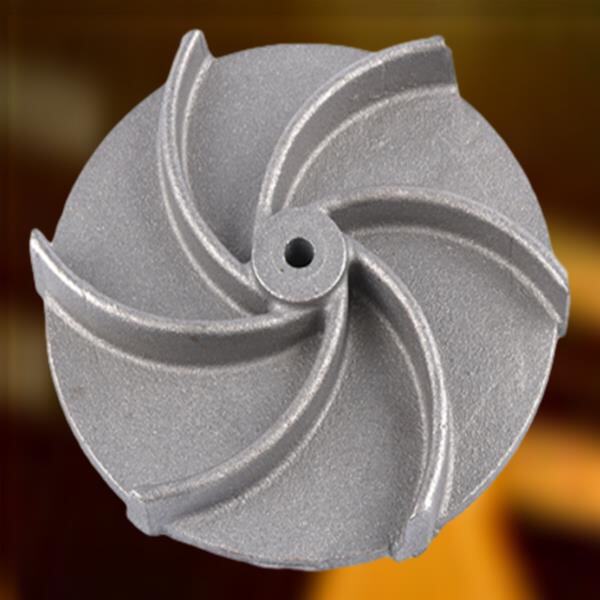

Ако производителите на модели разполагат с надеждно оборудване, могат да изграждат точни модели. LF осигурява оборудване като инструменти за рязане, машини за формоване и 3D принтери. Инструментите за рязане създават модела, а машините за формоване създават формите. 3D принтерите генерират сложни форми от проекти, произведени от компютри.

LF е един от най-добрите доставчици на материали за изработване на модели. Те разполагат с голям брой висококачествени инструменти, материали и оборудване, които позволяват на създателите на модели да правят точни модели. Производители на модели по целия свят разчитат на продуктите на LF поради тяхната надеждност и качество.

Ние, производителите на литейни модели, доставяме на повече от 100 клиента, които са персонализирали своите нужди, бързи, точни и ефективни решения за персонализация. Можем да задоволим широк спектър от изисквания на клиентите, независимо дали става въпрос за пълна персонализация или персонализация въз основа на дизайн. Гарантираме, че всеки персонализиран проект се изпълнява по най-професионален начин.

Ние, производителите на литейни модели, доставяме на нашата литейна фабрика, постигайки интеграция на производството и търговията. Качеството и цените ни са по-високи от тези на 90 % от производителите на пазара. Елиминираме посредниците и можем да предложим конкурентни цени и продукти с по-високо качество директно от нашата фабрика до нашите клиенти.

Отделът ни по обслужване на клиенти е на разположение 24/7, което гарантира, че въпросите ще бъдат отговорени в рамките на 1 час, оферти ще бъдат предоставени в рамките на 12 часа, а материали и решения за изработка на модели за литейни форми могат да бъдат доставени също в рамките на 12 часа. Независимо от времето или мястото, от което нашите клиенти ни контактуват, те могат бързо да бъдат достигнати и да получат професионална помощ, като се осигурява задоволяването на техните нужди навременно.

Разполагаме с линии за доставка на материали и компоненти за изработка на литейни модели, CNC машинни центрове и работилници за повърхностна обработка, които съвместно осигуряват техническа поддръжка за серийно производство. Производствените ни възможности ни позволяват да изпълняваме поръчки както в големи, така и в малки количества, като поддържаме най-високите стандарти за качество и ефективност в производството.