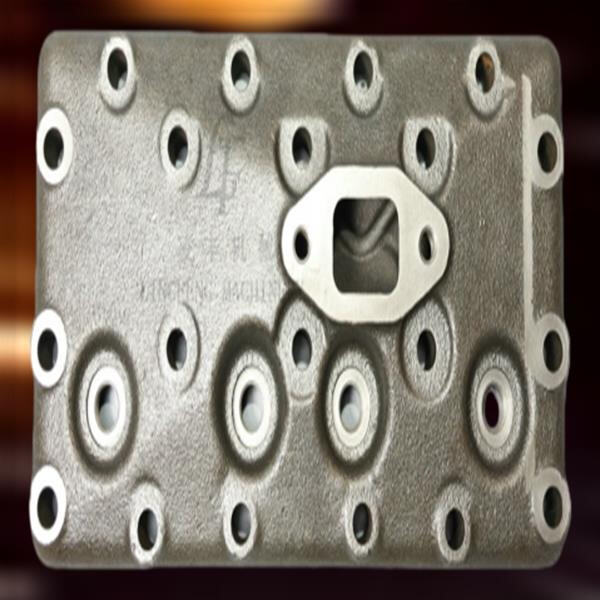

Having a problem with your cast iron manifold on your car. Don't worry, let LF company handle all your welding needs. The cast iron manifold, an occasional break and/or tear in your car's essential component. Cast iron is a tough metal to weld and these tips will help you to repair it, grey cast iron casting as needed. These are just a few simple steps on how you can walk through the process of welding your manifold. Clean the manifold well.

Heat the manifold. Cast iron does not heat up like other types of metal. Heating the area being welded to the back side will help prevent it from cracking. It is easier to weld and often makes for a much better bond when the Metal is warm. Before you start to weld grey iron castings you can heat the manifold up with either a torch or heating blanket.

Use the proper weld rod. Welding rod for cast iron: It's great to go with the right one. It needs a kind of rod, which is generally nickel. More aggressive and far much more flexible than your usual rods that are made of nickel Having been welded with the proper rod makes it sure that it will not break up under tension once put on a car, and that is very important for safety and performance.

This is absolutely essential because cleaning of the manifold before welding is very critical. Take some time and clean away the rust, dirt, or old grease from the area where you are going to weld. The cleaning also is crucial because it prepares the manifold to the new metal that bonds relatively easier. If the surface is dirty, the weld cannot hold correctly and that will give more trouble later.

Set a low amperage. The welder produces heat according to the amperage level you set your welder to. Cast iron, by the way, is a brittle material-this means that if it overheats, cast iron grey is the possibility of it cracking. So when you do weld you need to have a low amperage setting, in that way any possible damage and cracking will be avoided in the cast iron.

Prepare the new metal. After that is a piece of new metal, thickness same as your manifold Take a small piece and make cuttings at the right place. This new part must be clean and free of corrosion or dirt. As was same with the manifold, noise will be a low pressure cast iron price, if the new metal is not clean this could be a problem for the weld.

Put the new metal on. Now that all that new metal is prepped it is time to install it to manifold using your welder. In order to tack the new piece into place against the manifold, use a low amperage setting on your welder. Think of tacking as putting little fast welds down to spot the new metal where it goes. The latter reason this is necessary because the newly added metal would shift while you finish the weld.

Our production lines are automated Welding cast manifold and surface treatment workshops that work together to provide technical support to support mass production Our manufacturing capabilities allow us to process orders from small quantities to large ones while maintaining the highest quality production standards and efficiency

Over Welding cast manifold customers have been serviced by us, providing fast precise and efficient solutions. We are able to satisfy a wide array of requirements from customers whether they require total customization or design-based customization. Our knowledge and experience guarantee that every customized project will meet the client's expectations.

We own Welding cast manifold own casting facility which allows us to integrate production and trade. We have lower prices and better quality than the majority of our competitors. By eliminating the middleman, we offer more competitive prices and better quality products directly from factories for our customers.

Our customer service team is always available making sure that inquiries are responded to within a matter of hours quotations are sent within 6 hours and custom solutions can be delivered within Welding cast manifold Whatever time or place our customers reach out to us we will respond promptly and offer professional assistance making sure their needs are satisfied quickly