Sand could be exactly what you need if you are looking for a unique and creative hobby! One of those processes is called sand casting, where you sculpt sand into freeform shapes and pour hot metal in them to create a wide variety of things. They can be anything from toys to beautiful pieces of art. If you are new in doing this will be slightly difficult for the first time, but relax! It's definitely a skill you can develop — after a bit of practice and patience, and it will be an enjoyable one for a life-time

Here is a list of things you will need to collect before you start off your sand casting adventure: To begin with, you will want some sand. Sand is relatively easy to acquire at a local building supplies store which is often a hardware store or a home improvement store. After that, you also need a mold box. This is a thing that keeps the sand in place while making your mold. You will also need a pattern, which is the outline of the object you wish to create. Lastly, you will need a few tools to help you sculpt and mold the sand.

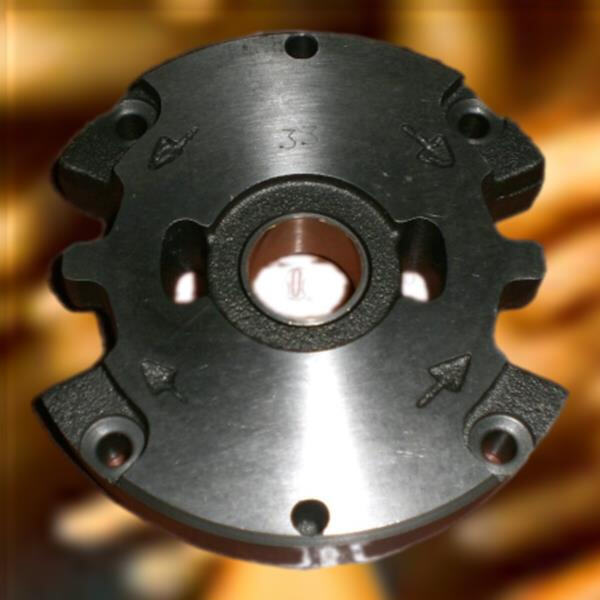

With all your supplies sorted, you need to get down to business to make your mold! For this you must first fill into the mold box. Ensure that the sand is tightly packed so that it does not lose its shape. Your pump casting mold is probably not going to come out right if you do not pack your sand tightly. Once you have filled and packed the sand, carefully press your pattern into the sand. Be sure to press down to make a clean impression. Now that you have pressed your pattern into the sand, you can gently lift the pattern away from the sand. You would see a perfectly, cast mold in the sand

Finally you can pour your hot metal into the mold! This section is tricky, so its best to have a buddy who has some sand casting experience if possible. Never forget about protective equipment, gloves, and goggles are vital while handling hot metal. Safety is very important.

As the hot metal goes into the mold, it will begin to cool and solidify. After you leave it for a couple of minutes you have to gently take out the mold from the sand. Check out your creation when you take it out. If all went well, you should now have a lovely new something you can show off or share as a gift.

Sand gray iron castings Pack – Be sure your sand is securely packed. Issues with sand not being compact enough means your mold wont hold its shape and your object will most likely not come out correctly.

Leave Room for Molding — Mold the sand casting foundry into a definitive shape with your tools but do it with caution. This step is very crucial to the success of your project, so do not rush through, please!

The casting plant we operate is owned by us, which enables us to combine production and Sand casting for beginners. Our prices and quality are higher than 90% of the companies on the market. We eliminate the middleman and offer our customers more competitive prices, superior products and direct from the factory.

Our customer service department is available 24/7 ensuring that questions are addressed within 1 hour quotations are delivered within Sand casting for beginners and solutions for customization can be delivered within 12 hours Whatever time or place our customers contact us they can be reached quickly and offer professional assistance making sure their needs are satisfied in a timely manner

Over Sand casting for beginners customers have been serviced by us, providing fast precise and efficient solutions. We are able to satisfy a wide array of requirements from customers whether they require total customization or design-based customization. Our knowledge and experience guarantee that every customized project will meet the client's expectations.

We have automated production lines CNC machining centers and surface treatment Sand casting for beginners that work in tandem to provide technical assistance to support mass production We have the manufacturing capability to fulfill requirements of any size and still maintain production standards