Bidirectional (aka Grey cast iron sand casting)This is a pretty cool art that has been used for quite some time. This is where hot melted metal is poured into a sand mold to create various pieces. Now here for find out the benefits of this method and its revolutionisation in the industry today.

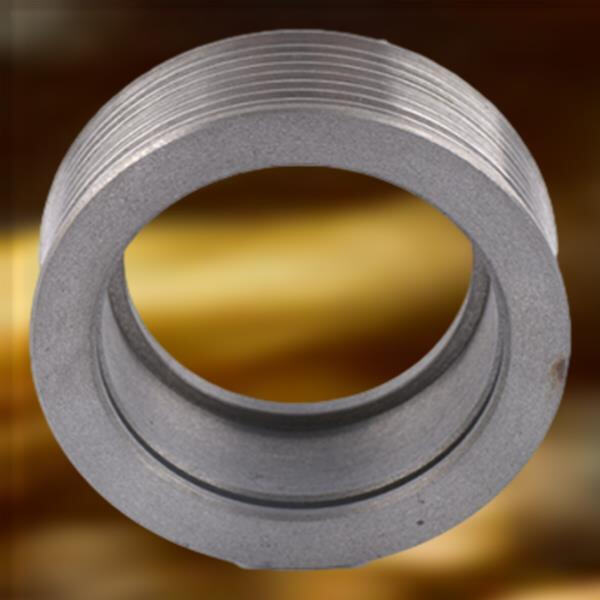

Grey cast iron sand casting is a sand molding process of sand poured over in melted metal. This is capable of making things such as tools, machine components, and beautiful decoration. It is an old technique that has been used for 1000s of years and remains a popular option today because it is practical and not too expensive.

You begin by making a mold of the piece you wish to design. The hard model or positive is used to produce a sand mold. When the mold is prepared, hot molten metal is poured and is allowed to cool down and solidify. The mold is then broken up, and the finished object lives in there.

Grey Cast Iron Sand Casting And Its Shapes Grey cast iron sand casting is 1 of the best methods that allow you to make goods with different designs and details. This form of manufacturing can create is, items that would be difficult or impossible to create using alternative techniques.

Applying grey cast iron sand-casting does not cost too much, which is another reason to use it. This process is more advantageous than the other processes of casting, so it becomes a process of choice for the people who want to make high-quality products at low prices.

Based in India, grey cast iron sand casting for manufacture of low-cost, high-quality products represents a breakthrough in casting technology that will revolutionize the manufacturing industry. This ancient method remains popular today as it is capable of building elaborate shapes with a high level of detail.

Grey cast iron sand casting enables the manufacturers to create products that would be difficult or impossible to manufacture with other processes. It this way you also get massive strength and durable, so it is best for tough and long last things.

Our customer service department is available 24/7 ensuring that questions are addressed within 1 hour quotations are delivered within grey cast iron sand casting and solutions for customization can be delivered within 12 hours Whatever time or place our customers contact us they can be reached quickly and offer professional assistance making sure their needs are satisfied in a timely manner

We own our own manufacturing facility for casting, achieving the integration of production and trade. Our prices and quality is superior to that of 90% of the suppliers in the market. We cut out the grey cast iron sand casting and give our customers competitive prices, superior products and direct from our factory.

The automated production lines we have CNC machines and grey cast iron sand casting workshops all work together to facilitate mass production We have the capability to fulfill requirements of any size with the same production standards

We've served more than 100 customers who have customized their needs, offering rapid, precise and reliable customizing solutions. If you're looking for full customizing or grey cast iron sand casting we are able to meet a variety of customer needs. Our experience and expertise ensure that every project we create is in line with the expectations of the customer.