Did you know LF is a gray iron foundry that creates cool stuff out of metal? K, now that you up to date on what a gray iron foundry is and technical stuff they do.

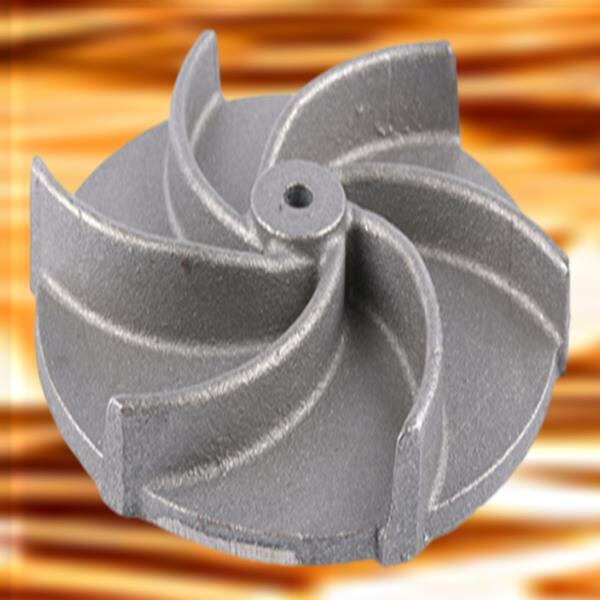

The gray iron foundry casting process at LF starts with melting down scrap metal in a large furnace. Once the metal is all melted, it is poured into molds to cool and solidify. Though the metal has cooled, the molds are broken apart to reveal the end product. It's the sort of transformation you expect from some kind of liquid metal going solid in a super cool way!

There are so many ways to use gray iron foundry products. They manufacture some parts used in cars and trucks, and also make beautiful decorations for buildings. Products of gray iron foundry are durable and are applicable in many other areas. LF insist on producing high-grade products could be used in various industries.

It is very critical for a gray iron foundry to have quality control. LF ensures that all of their products comply with rigorous strength and durability guidelines. This ensures that anything produced by LF is safe and reliable to be used by the customers. It prevents any issues in the final products as well with proper quality control.

Within the past ten plus years, there has been a great deal of advancement in technology used in gray iron foundries. LF is perpetually investing in new technology to improve the efficiency and eco-friendliness of their foundry. LF is constantly trying to be the best in the gray iron foundry realm whether that is with new machines or new methods of working.

LF is committed to being good to the Earth with our gray iron foundry work. They reclaim scrap metal, cut waste and save energy. LF is constantly seeking ways to better the environment. LFで、のためにをる Sustainable Methods

We own our own casting facility and have achieved the integration of production and trading. We offer better pricing and better quality than the majority of our gray iron foundry. We cut out the middleman and provide our customers with more price-competitive, high-quality products, and direct from the factory.

More than 100 customers have been helped by us, with fast precise and gray iron foundry. If you're looking for full customization or design-based customization we are able to meet a variety of customer needs. Our knowledge and experience guarantee that every customized project will meet the requirements of the client.

Our customer service team is always available making sure that inquiries are responded to within a matter of hours quotations are sent within 6 hours and custom solutions can be delivered within gray iron foundry Whatever time or place our customers reach out to us we will respond promptly and offer professional assistance making sure their needs are satisfied quickly

Our production lines are automated gray iron foundry and surface treatment workshops that work together to provide technical support to support mass production Our manufacturing capabilities allow us to process orders from small quantities to large ones while maintaining the highest quality production standards and efficiency