Gray cast iron is a very strong gray metal. Steel is produced by smelting iron and combining it with some other materials to create several sturdy and resilient metal. [1] Because of this property gray cast iron resists wear and rust, which is why its used in many products.

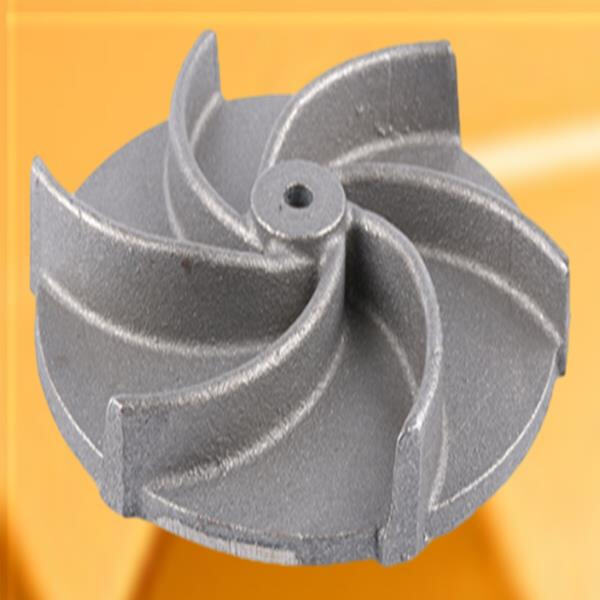

Gray iron parts are produced by the melting of iron and other materials using a furnace. The metal is melted, it is poured into a mold, and it is left to cool down and harden. It creates a durable piece of gray cast iron that can be mold for a wide variety of applications.

Gray cast iron has a lot of advantages that make it a desirable material for makers and builders. It is durable, long-lasting, and is resistant to wear and rust. That's why it's ideal for items such as machines, equipment, and automobile components. Further, it does not cost overmuch to produce gray cast iron, therefore it is often ideal for many companies.

On first glance, gray cast iron seems to have many good points, but when you put it next to other metal types, it is crucial to see what the better metal for a job is. For example, gray cast iron isn't as flexible as steel, but can better resist wear. It makes it a better option when strength and toughness outweighed flexibility.

That is why good-grade material and controlled processing are significant for providing good quality and durability in gray cast iron products. That means making sure to melt the metal properly, with the right ratios of the materials, and to keep a close eye on the casting process. These steps allow makers to produce durable and resilient gray cast iron products, suitable for a long-term service.