A ductile iron foundry is a unique type of factory that produces flexible and strong materials using iron. These materials are highly versatile as they can be molded into numerous items. Take for example ductile iron, which is used to manufacture crucial pipes, gears, and machines for a wide range of jobs and industries. This is because work done by ductile iron foundries supports many of the businesses and services that depend on strong materials. Ductile iron foundries are favourite over other foundries due to various reasons. Ductile iron features extreme strength and resilience as one of its best properties. It means a great deal of pressure can be applied & ductile iron will not break or be damaged. For this reason, it is widely used for heavy-duty applications, including construction-related and manufactured parts.

Moreover, ductile iron has resistance to wear and corrosion. It does not wear away nor does the rust need exposure to harsh conditions which means you can use it in harsh environment which may break down other materials. This durability is part of the reason why ductile iron products can last a long time and it is vital for companies that require dependable tooling and components. The added flexibility of ductile iron is another great aspect to it. This flexibility in structural shapes and sizes is when grey iron casting can be easily shaped and molded in any structural size and type. This property enables manufacturers to manufacture custom parts with an exact fit for the users. From a small piece to a large component, there can be no matter on the part size if a customer wants ductile iron as it can be tailored to the customers.

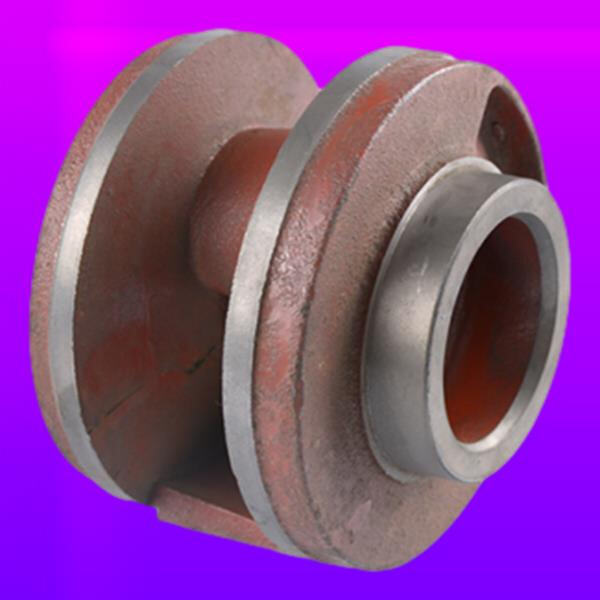

The LF molten metal is then then poured into a mold. The mold is specifically created to reproduce the shape of the part to be made. Once the molten metal is cast in the die cavity, the cooling process follows. Cooling helps the melted cast iron metal to set and take on the shape of the mold. The idea behind this is crucial because it leads to a finished product that is fully aligned with the original plan.

The ductility of ductile iron products is another significant advantage. LF's Ductile iron is also well suited to customization because it flows easily in its liquid state and so can be molded into pieces that meet the functional specifications for the customers. Which require that a company either need an ordinary component for its use or something particular and ductile iron can be designed according to that.

With the continual development of modern manufacturing technology, so rises a need for high quality components. With state-of-the-art machines and facilities, LF’s ductile iron foundry is designed to suit the modern-day requirements of factories. It enables them to manufacture components both fast and efficiently without compromising on the quality standards.

We have Ductile iron foundry over 100 customers who have customized their needs, offering fast, accurate, and effective customization solutions. We can satisfy a wide range of customer requirements regardless of whether it's complete customization or design-based customization. We ensure that every custom project is done in the most professional manner.

We have automated production lines CNC machining centers and surface treatment Ductile iron foundry that work in tandem to provide technical assistance to support mass production We have the manufacturing capability to fulfill requirements of any size and still maintain production standards

Our Ductile iron foundry service department is available 24/7 assures that every inquiry is promptly answered and estimates are made within 6 hours and custom solutions are made available within 12 hours No matter when or where our customers reach out we can promptly respond and provide professional service ensuring their needs are met promptly

We own Ductile iron foundry own casting facility which allows us to integrate production and trade. We have lower prices and better quality than the majority of our competitors. By eliminating the middleman, we offer more competitive prices and better quality products directly from factories for our customers.