Hi there! Do you know the Cast Impeller? It is a big word, but what so cool is that it promotes pumps! In this article, we will dig further into cast impellers and find out why they are relevant in factories.

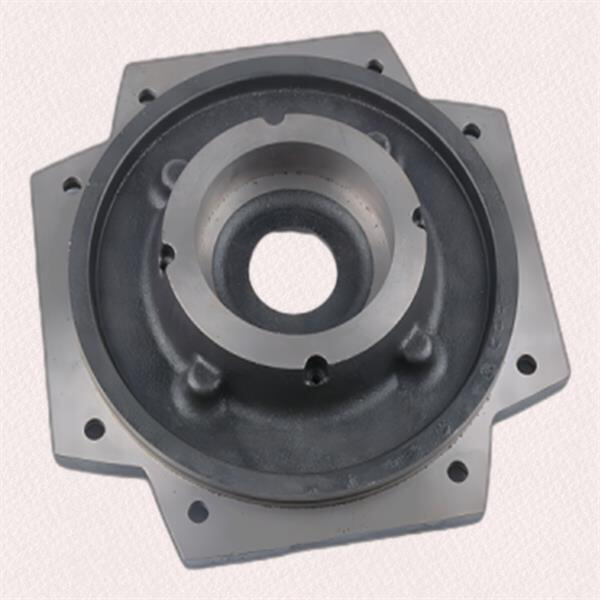

Let’s start with what a cast impeller is. A pump impeller is a pump component that rotates to cause moving water or liquids. A cast impeller is made by pouring hot metal into a mold, which gives it strength and smoothness. This is what makes cast impellers so effective at forcing liquids through a pump.

So, why do factories use a cast impeller? Cast impellers are built so well that they can handle tough jobs without breaking down quickly. Which makes them ideal for pumping water in factories, or moving chemicals through labs. They even save energy, and energy is good for our planet!

You may wonder how we are able to make casted impellers? It begins with the melting of metals such as stainless steel or bronze in a large furnace. From there, the metal is poured into a mold shaped like the impeller, once it’s hot. Once the metal cools and solidifies, the mold is removed and a shiny new cast impeller is ready to go!

Now, let’s look at what cast impellers do to make pumps more efficient. Cast impellers get a smooth and precise shape that makes the movement of liquid easy for them. That means pumps do not have to operate as hard, which reduces energy use and makes pumps last longer. To be fair, using a cast impeller can greatly benefit a pump's performance!

This is the next thing you need to choose if you want to use a cast impeller in your pump. Different materials and designs serve different purposes. So, make sure to do your research or consult an expert to help you identify the best cast impeller for your project. A pump with the correct impeller will perform at an optimal level!

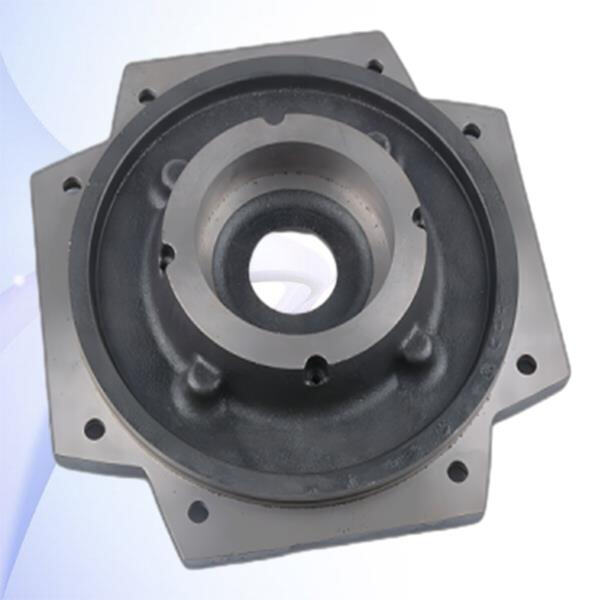

We own our cast impeller factory, achieving the integration of production and trading. Our prices and quality are superior to 90% of the manufacturers in the market. Because we eliminate middlemen, we are able to offer competitive prices and better quality products directly from the factory to our clients.

We have automated production lines CNC machining centers and surface treatment workshops that work together to provide technical assistance for mass production We have the manufacturing cast impeller to accommodate the demands of any size and still maintain production standards

Our customer service department is available 24/7 cast impeller that all queries are addressed within one hour while quotes are issued within six hours and customized solutions are offered within 12 hours We can respond promptly and professionally to our customers no matter which part of the world they are in or when they contact us

We've served more than 100 customers who have customized their needs, offering rapid, precise and reliable customizing solutions. If you're looking for full customizing or cast impeller we are able to meet a variety of customer needs. Our experience and expertise ensure that every project we create is in line with the expectations of the customer.